Cutting tools

Wood played a dominant role in this period, for use in dwellings, roofs, cathedrals, market halls, bridges and military structures. Woodworkers are likely to have taken a keen interest therefore in perfecting their tools. All the same, those tools have barely evolved since the Middle Ages, and even their names have changed very little. In his Histoire des charpentiers, Antoine Moles has studied the tools used by the carpenters corporation. From the 7th to the 9th century, carpenters’ tools consisted of large and small axes, cleavers, paring axes, large wood chisels, the characteristically French besaigue (bisaiguë) and the adze. These were later joined by augers to drill holes, then by saws, and finally by compasses and planes in the 14th century.1Moles 1949: 152–3.

The list of materials at the castle in Lille drawn up on 21 October 1388 also mentions a number of carpentry tools.2Prost 1902–1913, II: nos. 2331, 2333–36, 2338, 2341. Saws in particular are featured:

The following materials for use in carpentry:

First, 2 woodworking implements called levers [estauperches] and 1 rope belonging to the said levers [estaupierches], 36 toises long.3Editors’ note: 1 toise = 6 feet.

– 1 implement for loading wood, all rotten, and 1 rope belonging to it.

– 1 other turning tool with 2 wooden heads [tiestes].

– 1 winch for loading wood onto trestles.

– 2 saw horses for splitting wood and 2 large ropes.

– 4 ladders and 1 other large ladder for loading wood.

– 1 handcart for wood and three large wooden tables.

... etc.

Rough cutting

Hatchet or axe

One of the first tools and also one of the earliest weapons used by man was the hatchet or axe.4See Figs 55, 60 and 63. Held in the hand and designed as a bludgeon, it was a cult object for most primitive peoples before becoming a tool. This traditional implement evolved a little over the centuries, becoming a hatchet of different dimensions in the shape of large and small axes, which the carpenter wielded with great dexterity in one of his hands.

Trees for use in both construction and as firewood were felled by axe. The Registres des comptes municipaux de la ville de Tours refer in 1358 to ‘six days’ pay for him and fifteen days’ pay for other carpenters to fell, chop, and secure three cartloads of wood on top of the masonry of the wall’.5‘VI journées de lui et XV journées d’autres charpantiers, pour abatre, cognoier et asseoir III traines de bois pour faire dessus la maçonnerie du mur’; Delaville-Le Roulx 1878–1881, I: 45, no. 235. A little later, in 1365, two francs, four sols were paid for several days’ wages to Macé Équotin and Denis le Maçon (‘the mason’) for ‘cutting and cleaving certain wood purchased from Jehan de Rouen, taken from the forest of Banay, to build the bridge and barrier of La Riche’.6Delaville-Le Roulx 1878–1881, I: 369, no. 1,786.

Splitting axe

Smaller, and with a more convex blade, the splitting axe was used to cut up the felled tree.7See Figs 57, 58 and 61. Wood that was too freshly cut was carefully set aside. ‘Wood from the consignment purchased in 1396 could not be used, as it was too freshly cut and it was necessary to procure dead, dry trees in the forests of the Châtellennie de Vergy.’8Monget 1898: 293. The choice of trees to fell was determined by concern for the quality of the raw material and also, perhaps, by the requirements of royal ordinances. The trees felled were generally very large and almost past maturity. Prior to the 16th century, only tall, very old trees were selected for felling.9Deffontaines 1933: 148. Tools related to the axe include the cleaver, paring-axe and adze, which are still known today if Littré is to be believed.10Littré 1863–1877.

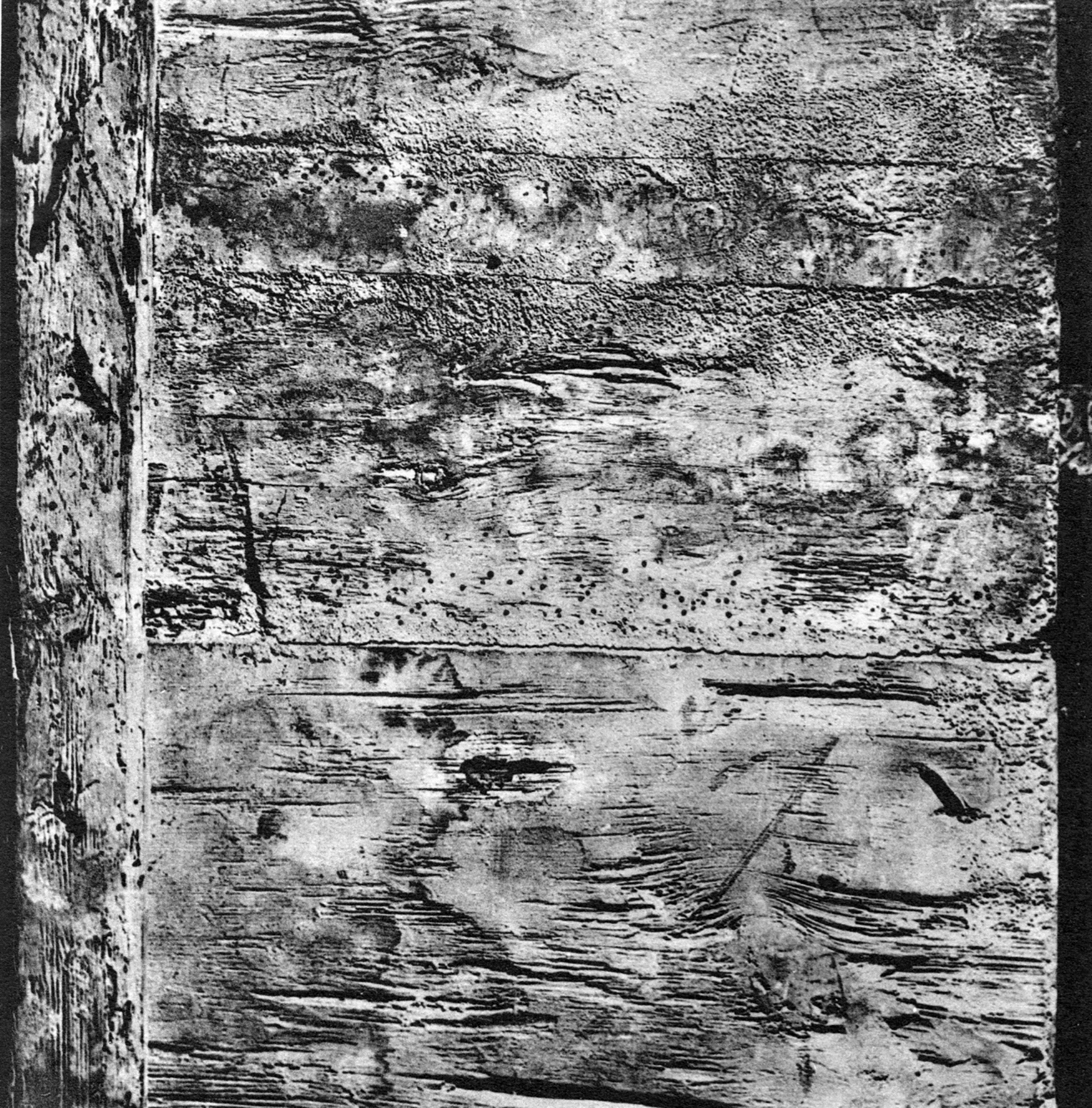

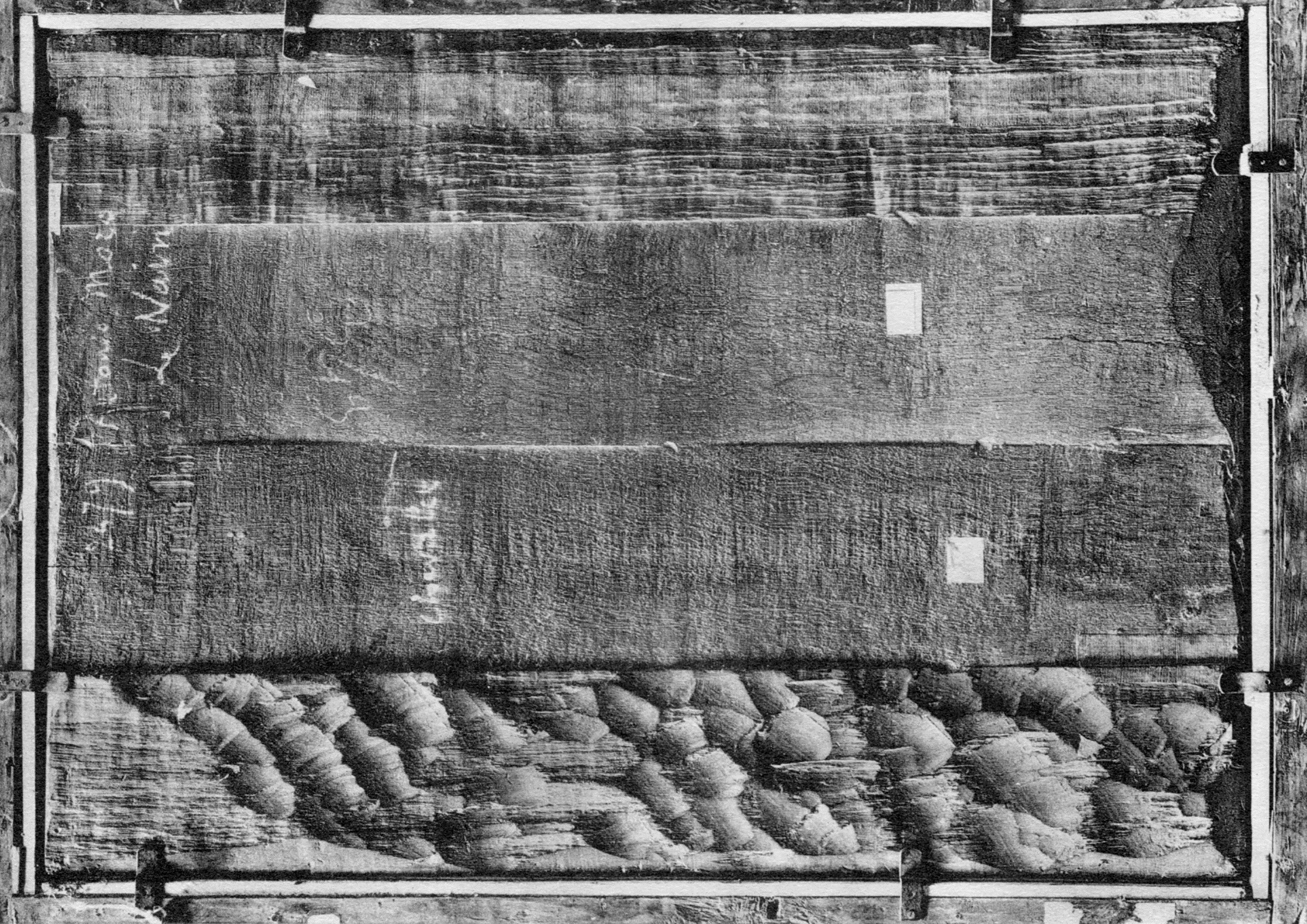

Cleaver

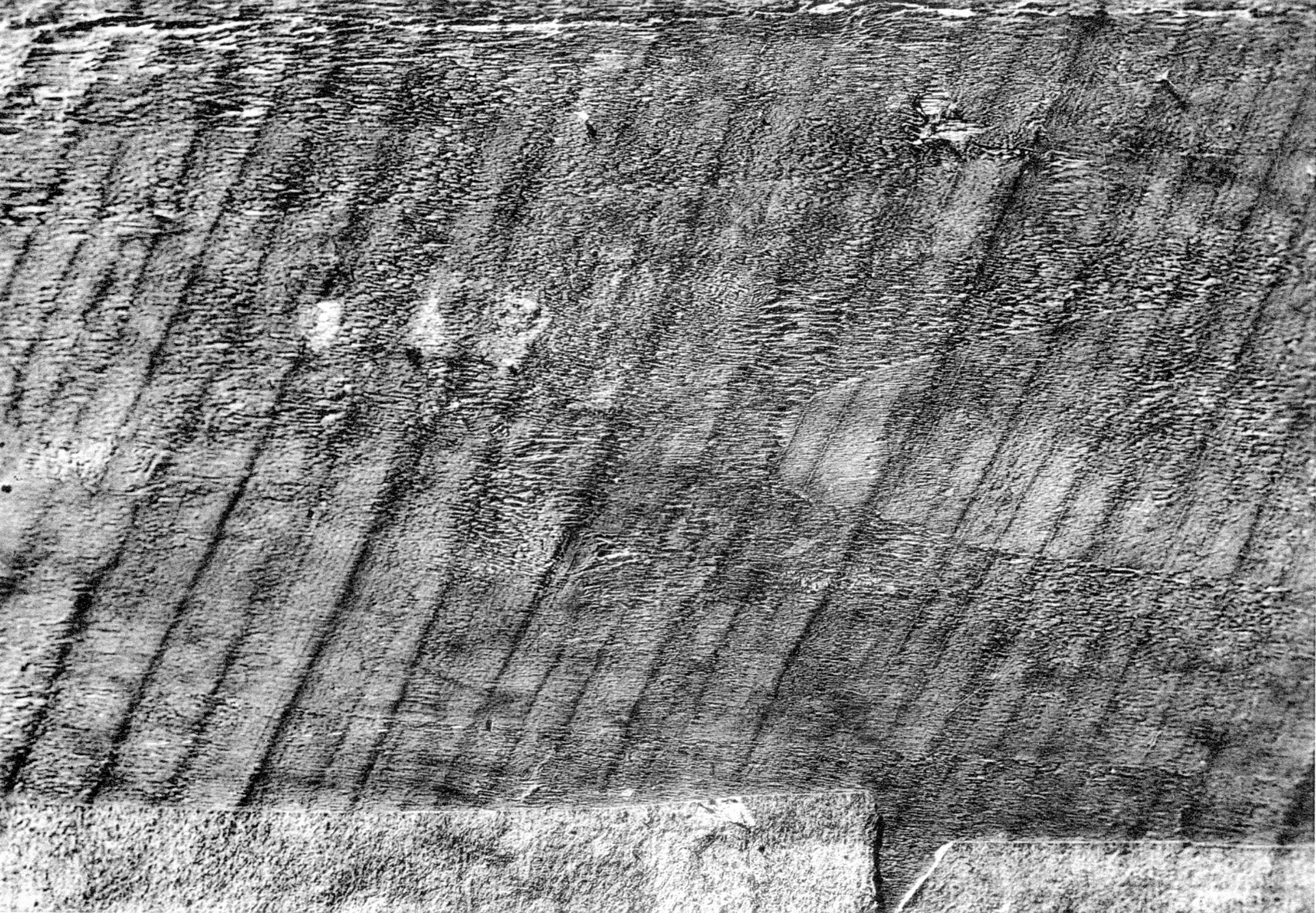

The cleaver (coutre) is also a kind of splitting axe: ‘Iron tool, commonly called a merlin, used to split wood.’ On 20 March 1374, a man from Argilly was paid 2 francs ‘for splitting by cleaver one thousand pieces of wood, known as bois d’Illande, each piece measuring five to six feet long and half a foot wide’.11Prost 1902–1913, I: no. 1,992. Different types of axe were used, therefore, to cut the felled tree into sections (ais or potz). Use of these tools does not leave any marks on the wood. As we can see from the back of the panel shown in Figure 68, the wood grain is clearly visible and the cut is rough but regular. The surface of the boards making up this panel12Catalan School, 13th century, Scenes from the Life of the Virgin, Barcelona (Painting index, no. 893). was cut with a splitting axe and has clearly not been smoothed very well. The wood looks more or less like it must have immediately after separation – split rather than carefully cut. The work is very basic yet undoubtedly followed a particular method. This is borne out by the statement that ‘splitting the wood avoids severing the fibres and vessels; split cask wood is far superior to sawn cask wood’.13Blais 1947: 181.

The practice of cutting panels in this way is very old. The cut surface was generally smoothed. A log split like this provided coarse boards, the rough faces of which were then ‘pared and smoothed’. At Champmol, ‘Henry Veinart, fine works carpenter, will pare and smooth 8 sections [aiz] of wood ... 10 foot long and one foot wide to make moles.’14Monget 1898: 59. Wood prepared in this way – by paring-axe, adze or draw-knife – has a distinctive appearance, depending on which tool was used.

Figure 51 Arms of the fustiers’ charity: a griffin holding an adze in its claws. (Ceiling boss, Chapelle de la Fusterie. Avignon, Église St-Agricol.)

Figure 52 Adze or paring-axe. (Gregorii moralia in Job, 12th century – Paris, Bibl. Nat.; Ms. lat. 15.675.)

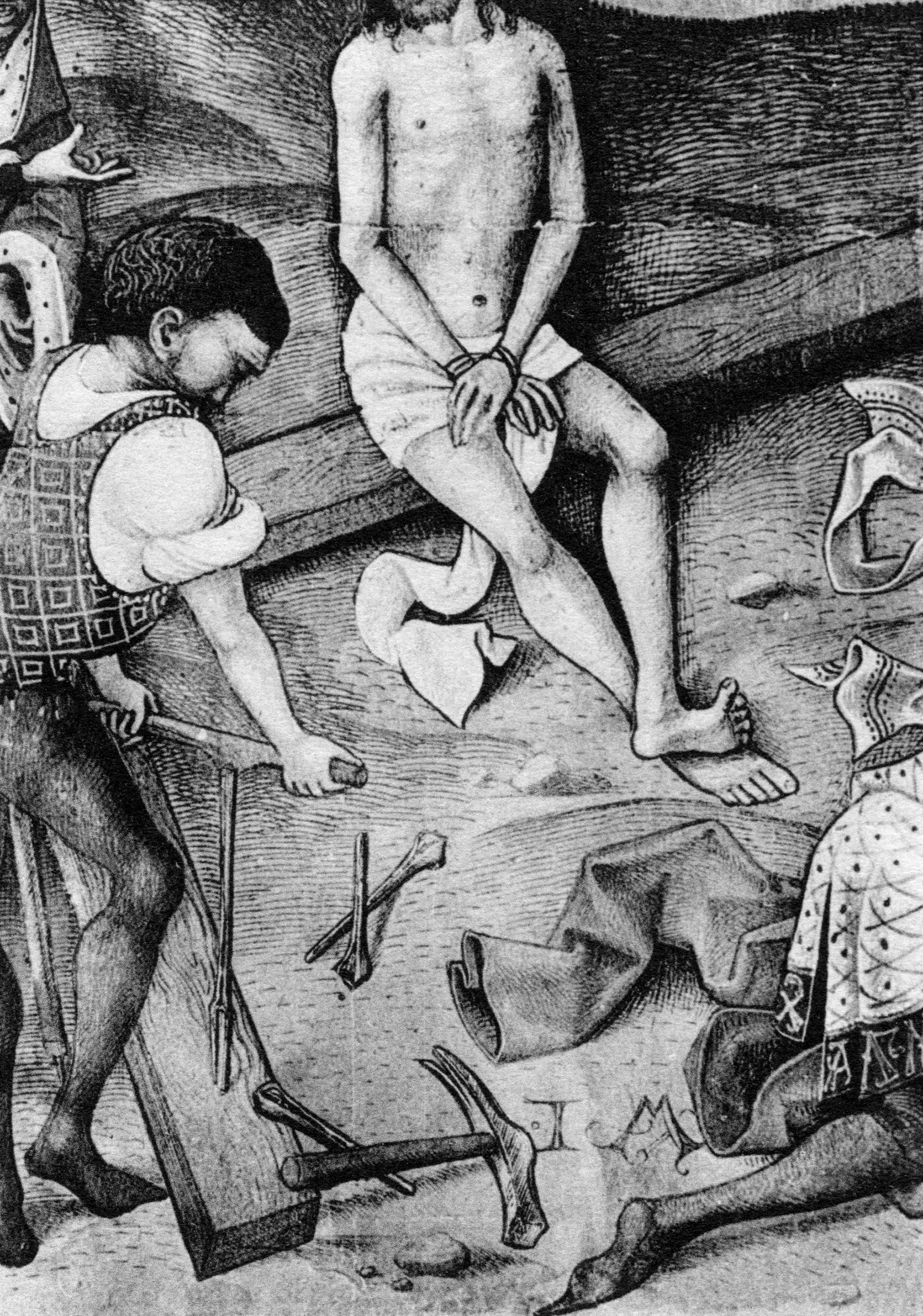

Figure 53 Auger and hammer: detail of an engraving by Isaac Van Neckenen. (Horae ad usum Parisiensem. Heures de Charles d’Angoulême, 14th century – Paris, Bibl. Nat.; Ms. lat. 1.173.)

Figure 54 Auger and adze. (Sébastien Mamerot, Passages faiz oultre mer, 1473 – Paris, Bibl. Nat.; Ms. fr. 5,594.)

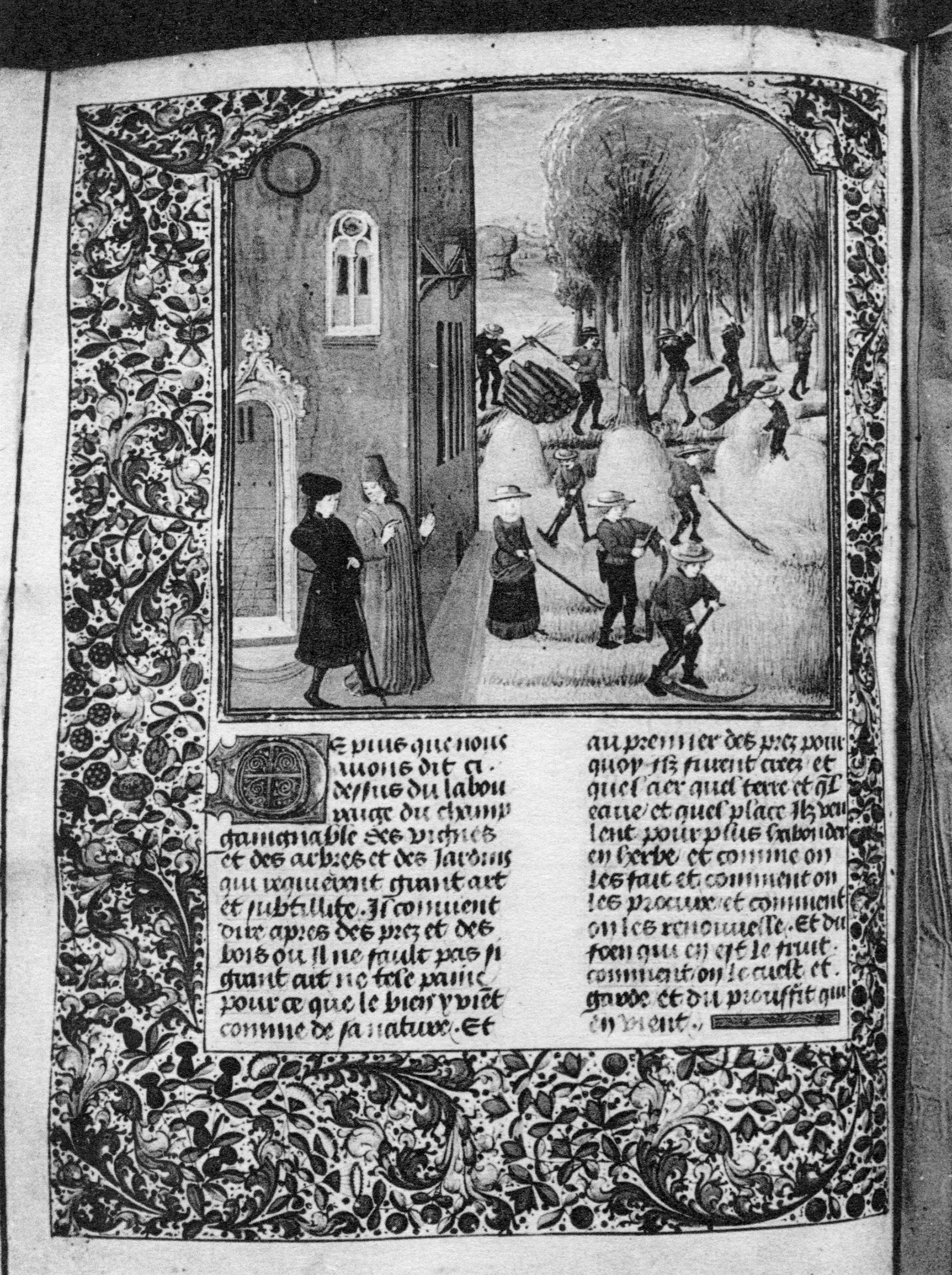

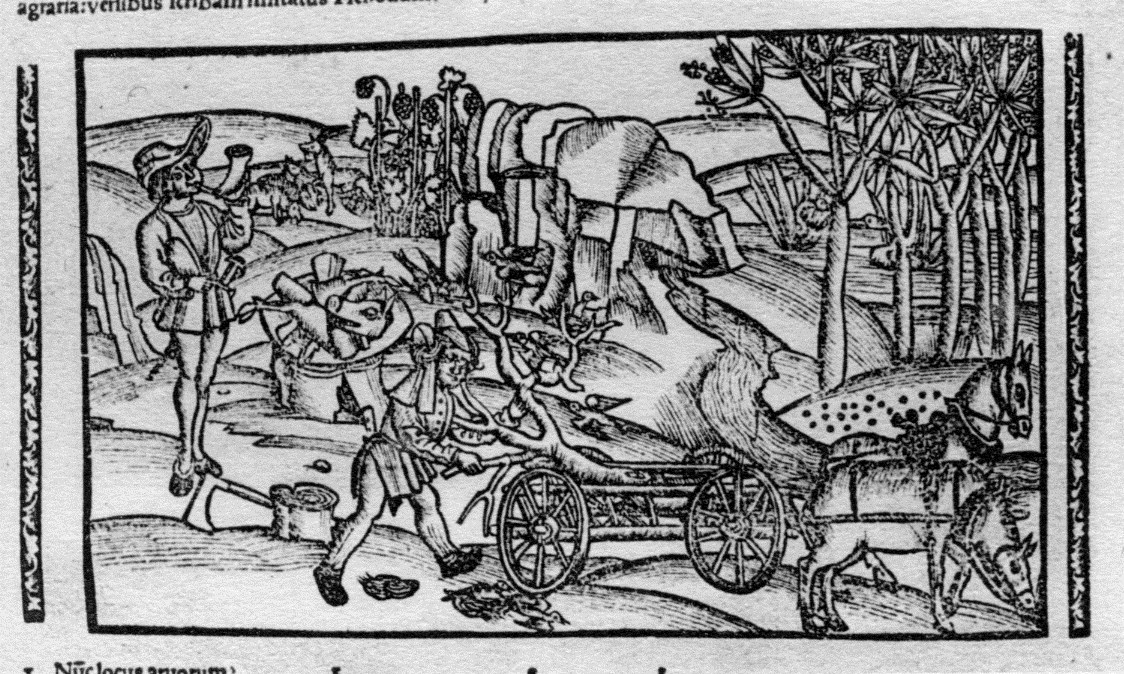

Figure 55 Axe. (Pierre de Crescens, Rustican. Exemplaire du Grand Bâtard de Bourgogne – Paris, Arsenal; Ms. 5.064.)

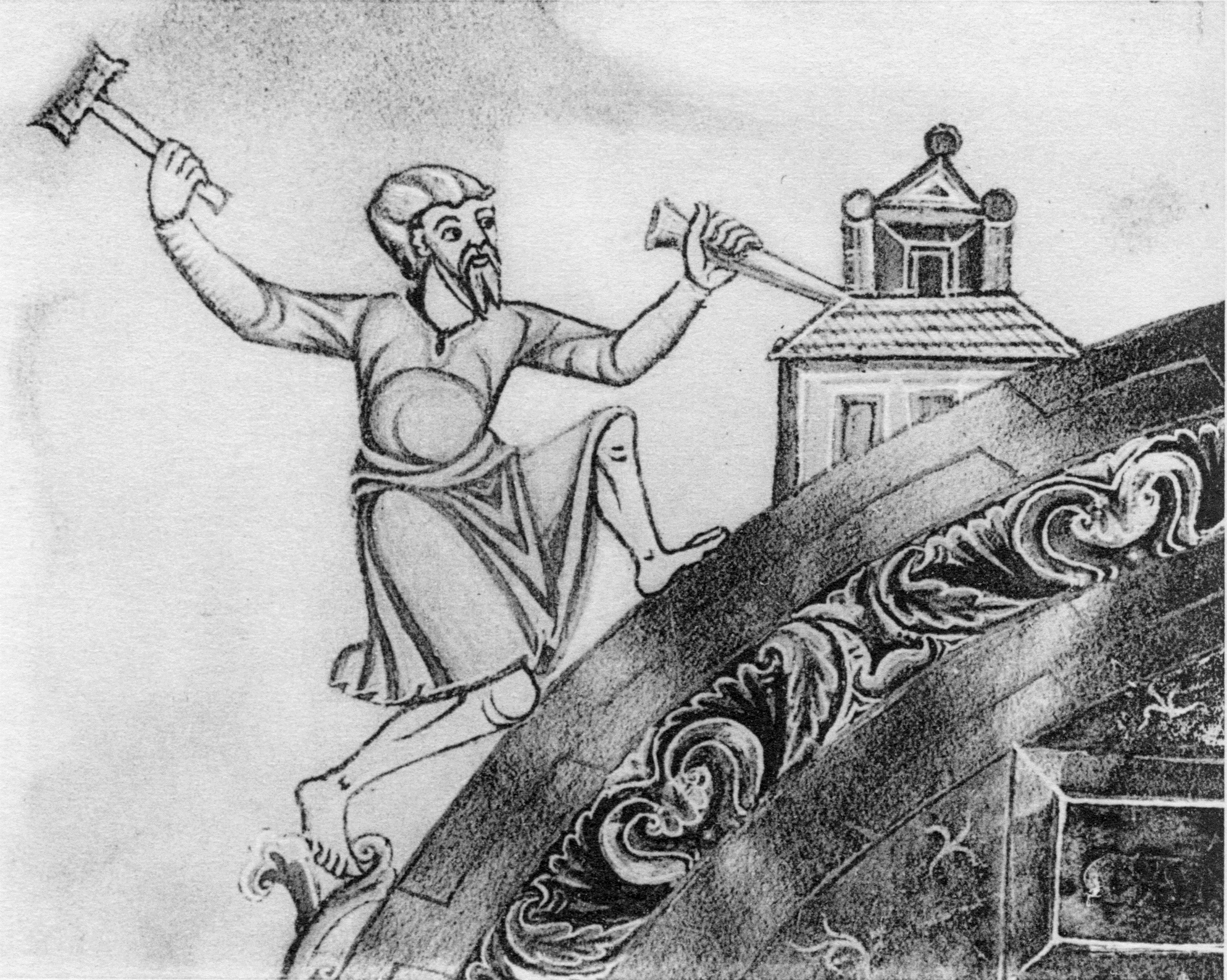

Figure 56 Mallet and wood chisel. (Gregorii moralia in Job, 12th century – Paris, Bibl. Nat.; Ms. lat. 15.675.)

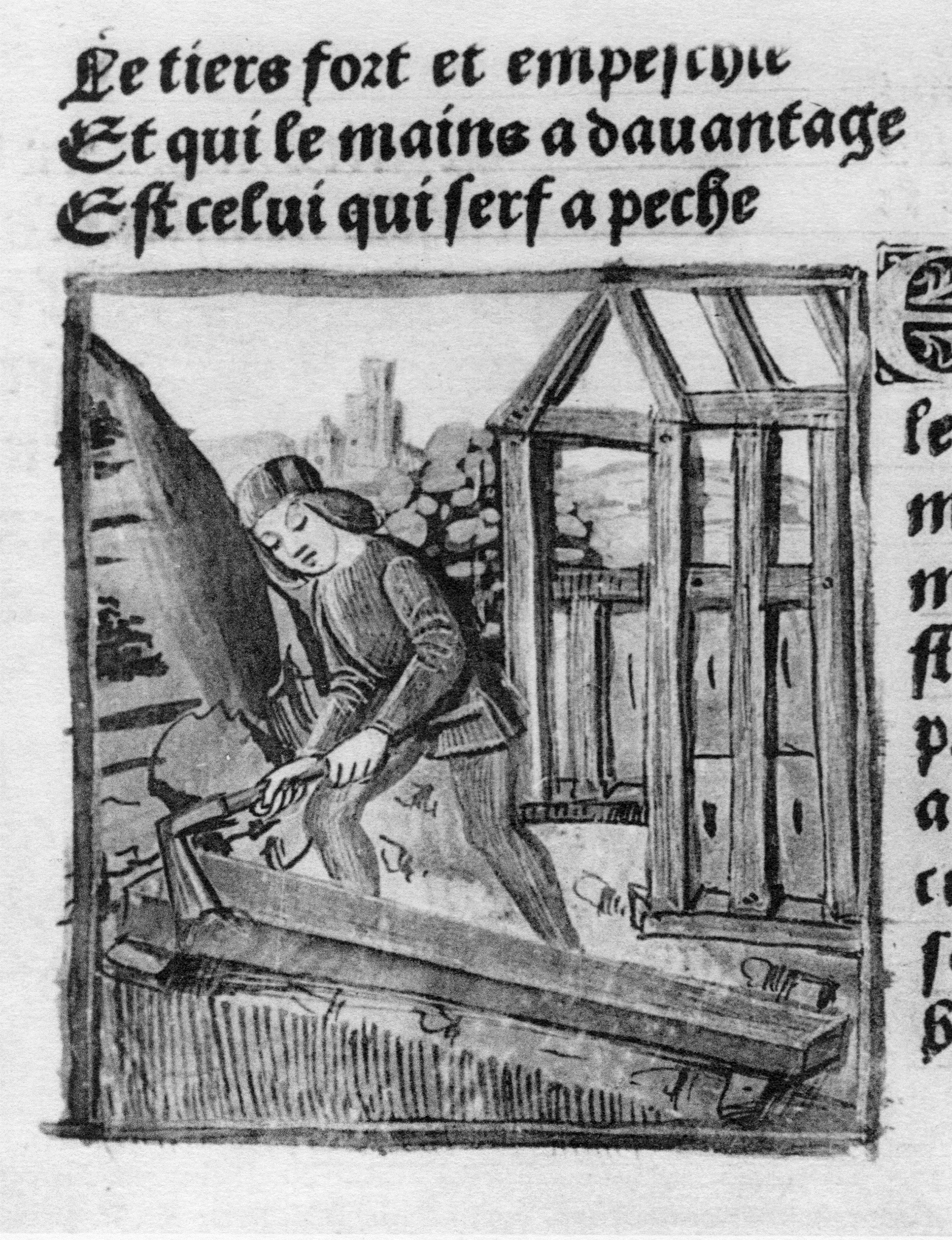

Figure 57 Adze. (Alain Duchartier, Les paraboles du maistre Alain en françois – Paris, Antoine Vérard. 1492. – Paris, Bibl. Nat.; lmp. Rés. vélin 580.)

Figure 58 Adze. (Saint Augustine, De la cité de Dieu. Trad. par Raoul de Pradelles, 15th century – Paris, Bibl. Nat.; Ms. fr. 18.)

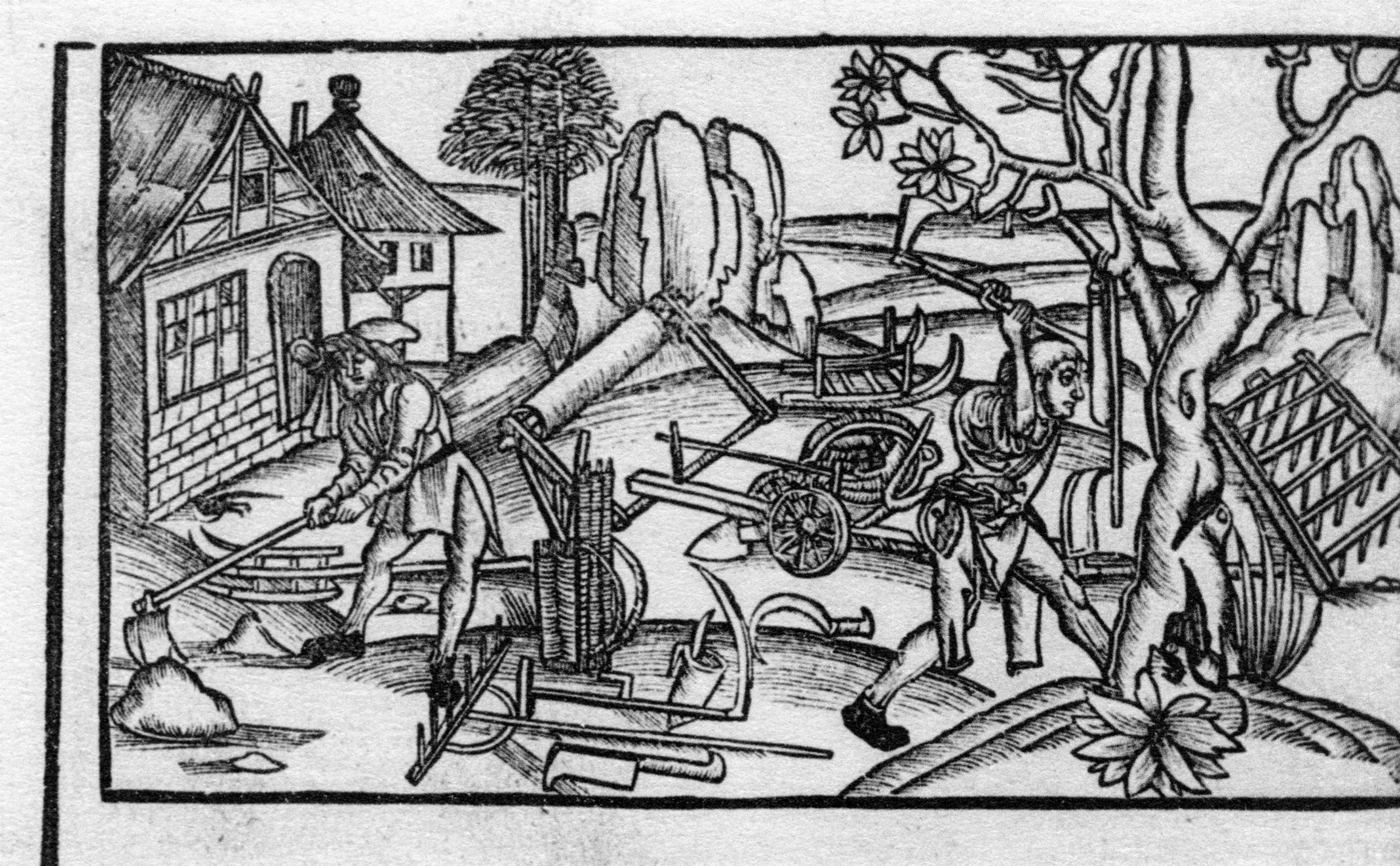

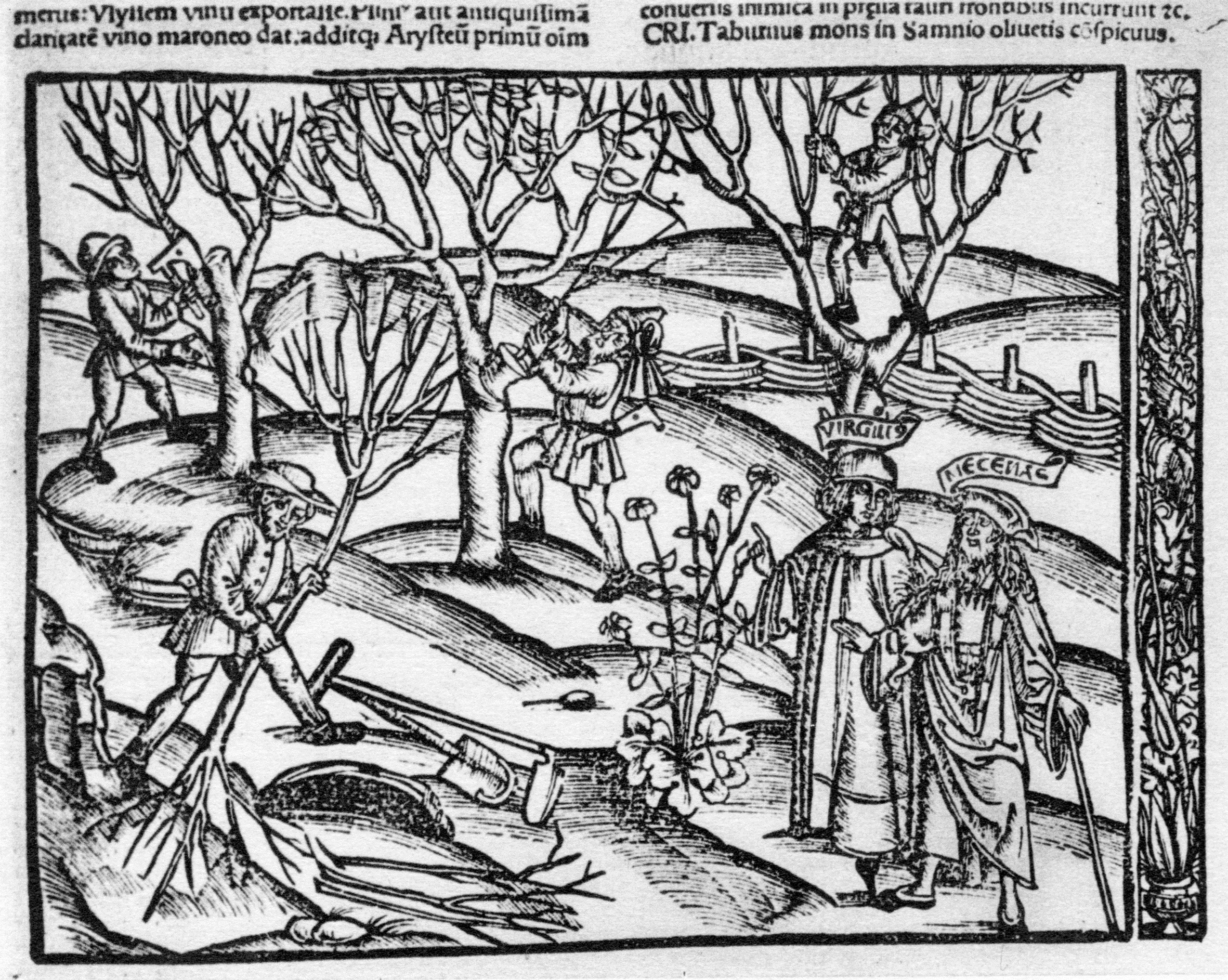

Figure 60 Axe. (Virgil, Opéra cum quinque commentariis Sébastiani Brant – Srasbourg, Johan Grieninger, 1502 – Paris, Bibl. Nat.; lmp. Rés. g. Yc 1052.)

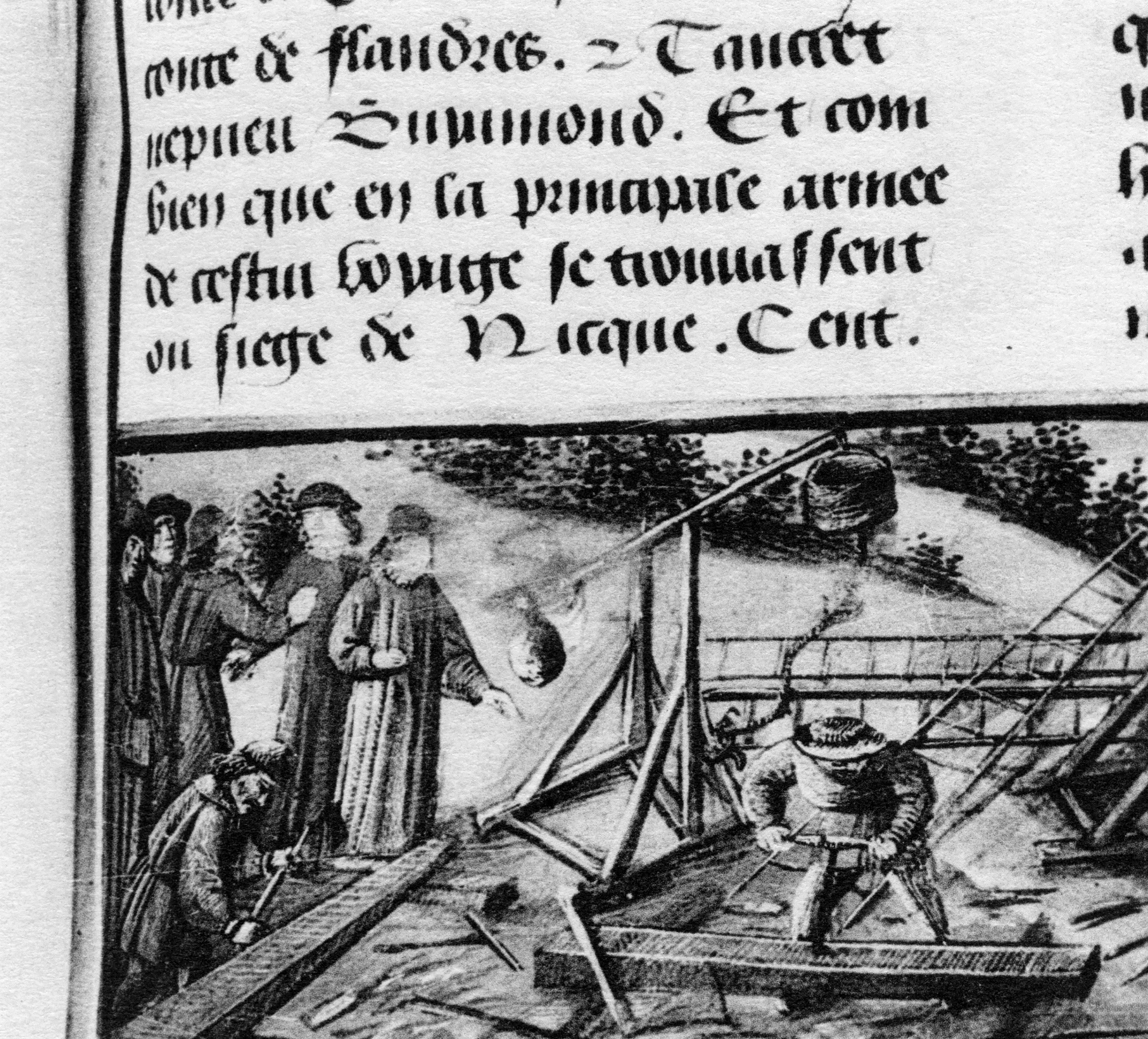

Figure 61 Saw, mallet and adze. (Sébastien Mamerot, Passages faiz oultre mer, 1473 – Paris, Bibl. Nat.; Ms. fr. 5,594.)

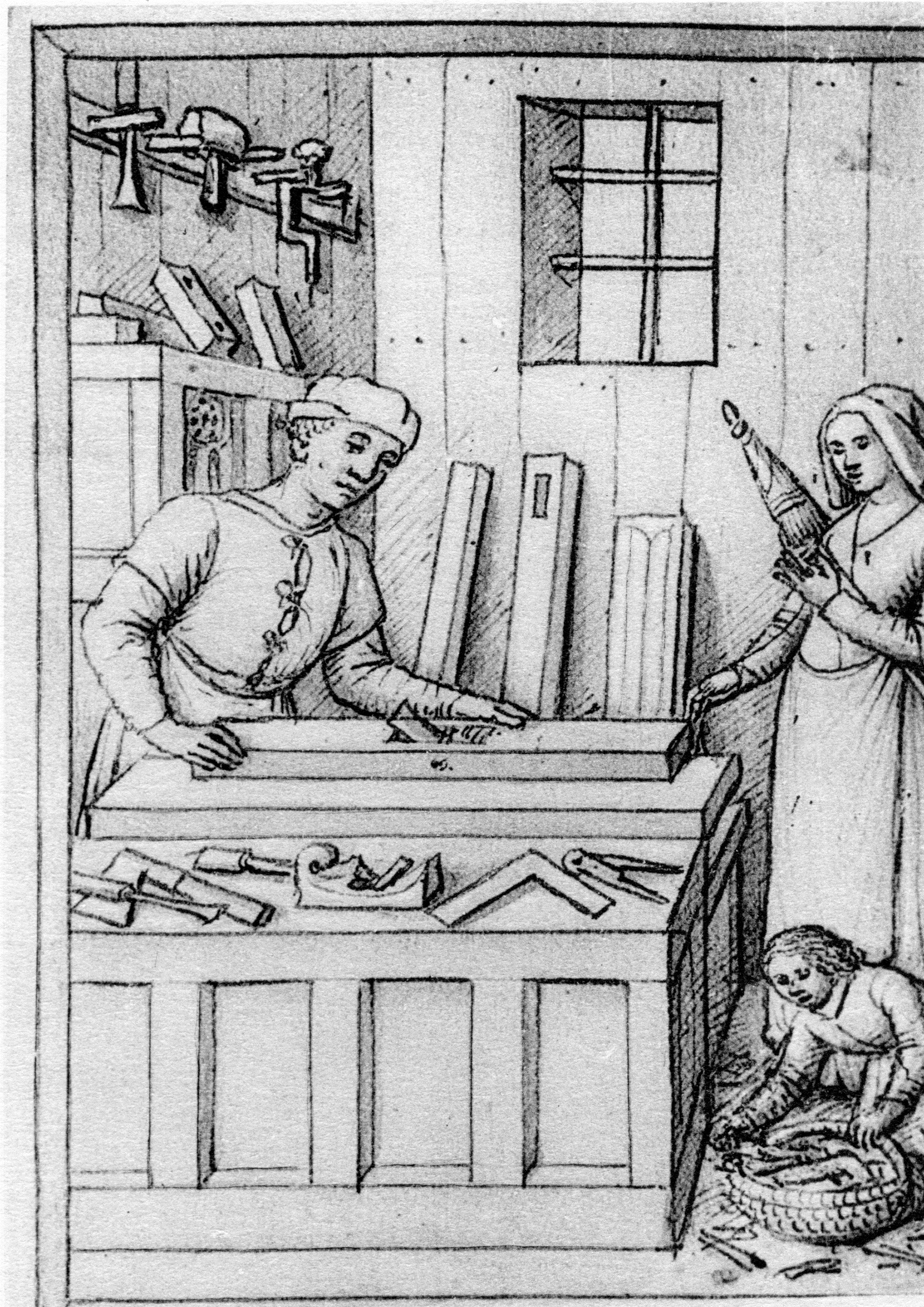

Figure 62 Hatchet, wood chisel, plane, square and compasses (in the foreground) and mallet, brace and bit (on the wall). (Deux ballades, 14th century – Paris, Bibl. Nat.; Ms. fr. 2,374.)

Figure 63 Transporting a felled tree: axe (Virgil, Opéra cum quinque commentariis Sébastiani Brant – Strasbourg, Johan Grieninger, 1502 – Paris, Bibl. Nat.; lmp. Rés. g. Yc 1052.)

Figure 64 Orchard. (Virgil, Opéra cum quinque commentariis Sébastiani Brant – Strasbourg, Johan Grieninger, 1502 – Paris, Bibl. Nat.; lmp. Rés. g. Yc 1052.)

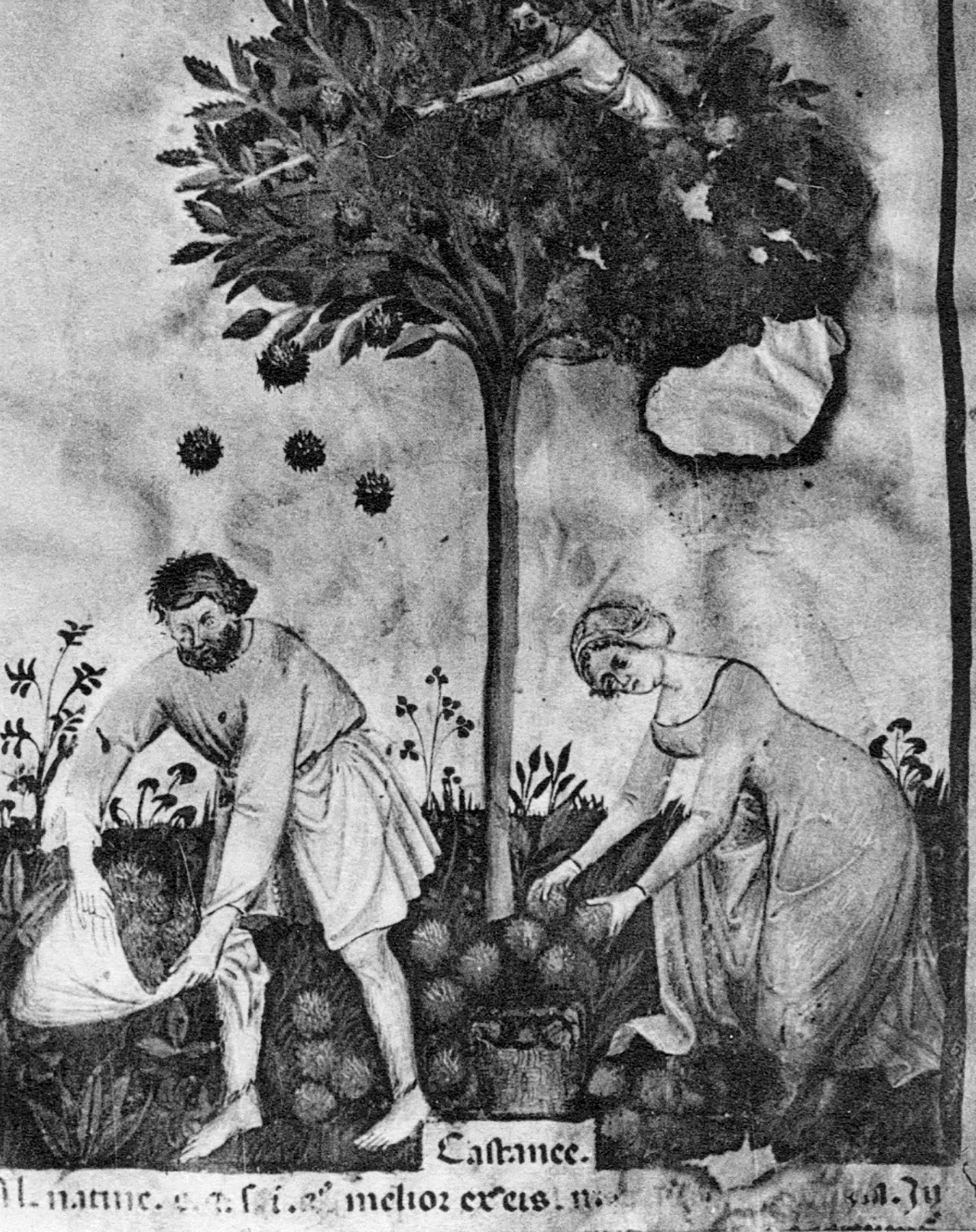

Figure 65 Chestnut tree: Gathering Chestnuts. (Albucasis, Tacuinum Sanitatis, 15th century – Paris, Bibl. Nat.; Nouv. acq. lat.)

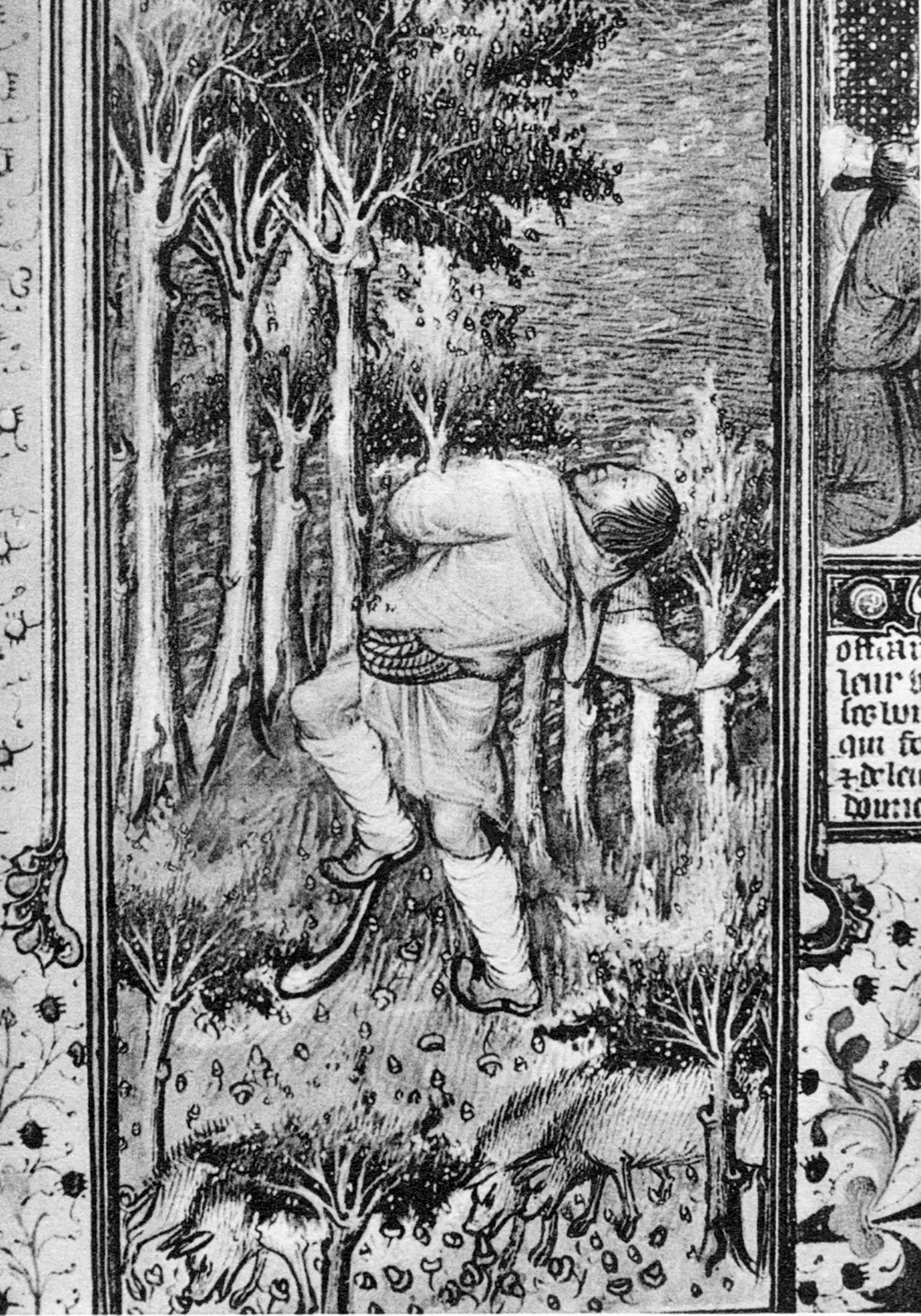

Figure 66 Oak tree: Acorn Harvest (Grandes heures de Rohan, XVe s. – Paris, Bibl. Nat.; Ms. lat. 9.471.)

Figure 67 Walnut: Beating a Walnut Tree. (Albucasis, Tacuinum Sanitatis, 15th century – Paris, Bibl. Nat.; Nouv. acq. lat. 1.673.)

Figure 68 Rough cut using a splitting axe. (Catalan School, 13th century, Scenes from the Life of the Virgin. Barcelona, Museu Nacional d’Art de Catalunya. Painting index, no. 880.)

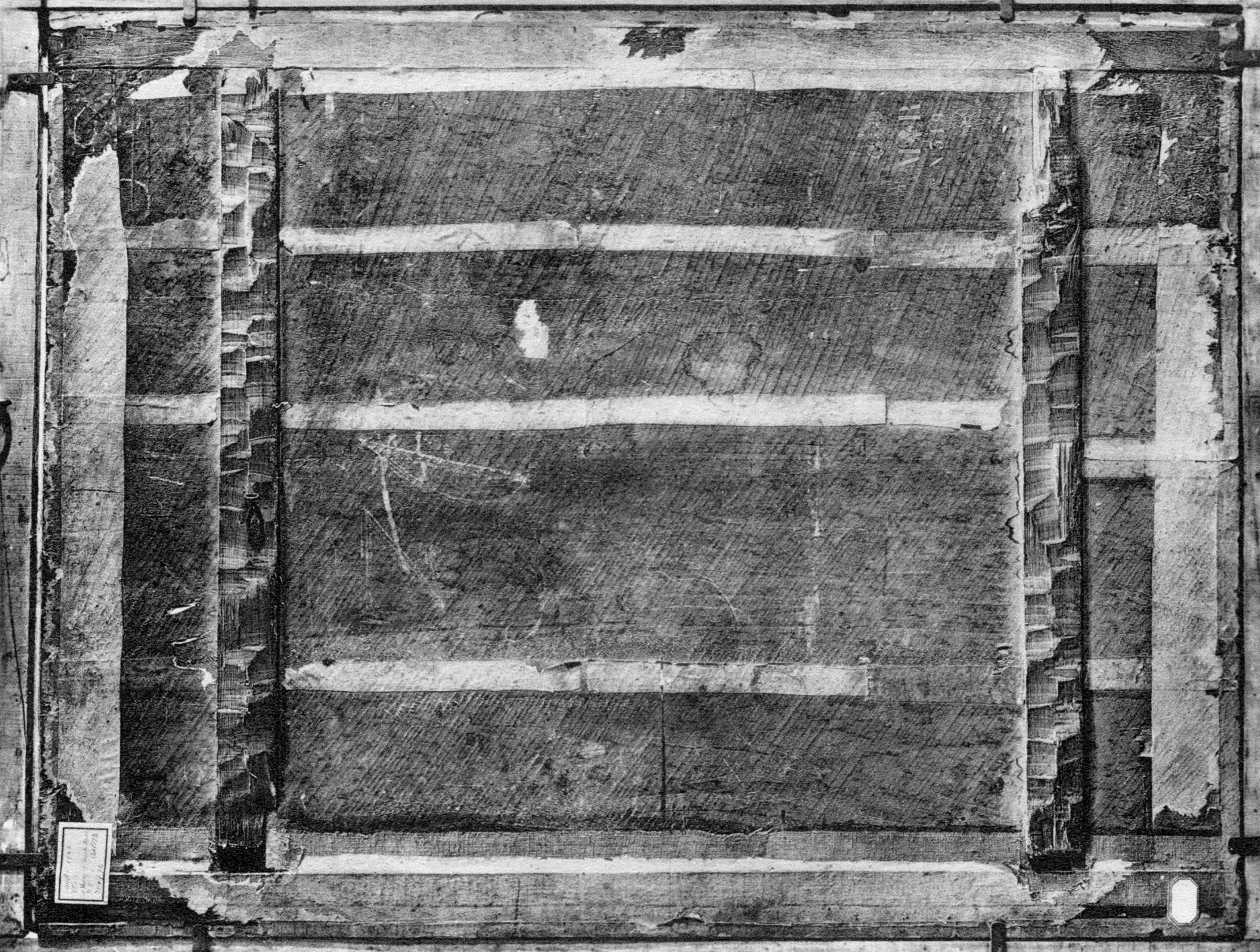

Figure 69 Rough cut using an adze. (Giovanni Massone, Triptych – Paris, Musée du Louvre. Painting index, nos. 651 and 653.)

Figure 70 Cut by an adze, saw and riving knife (left to right). (Antonio Moro, The Dwarf of Cardinal de Granvelle Holding a Big Dog. – Paris, Musée du Louvre. Painting index, no. 225.)

Figure 71 Cut by a saw (panel), flat wood chisel and mallet (cross-bars). (Leonardo da Vinci, The Virgin and Child with St Anne. – Paris, Musée du Louvre. Painting index, no. 602.)

Figure 72 Cut by a draw-knife. (Frans Pourbus the Younger. Portrait of King Henry IV of France in Black Costume. – Paris, Musée du Louvre, Inv. no. 1708.)

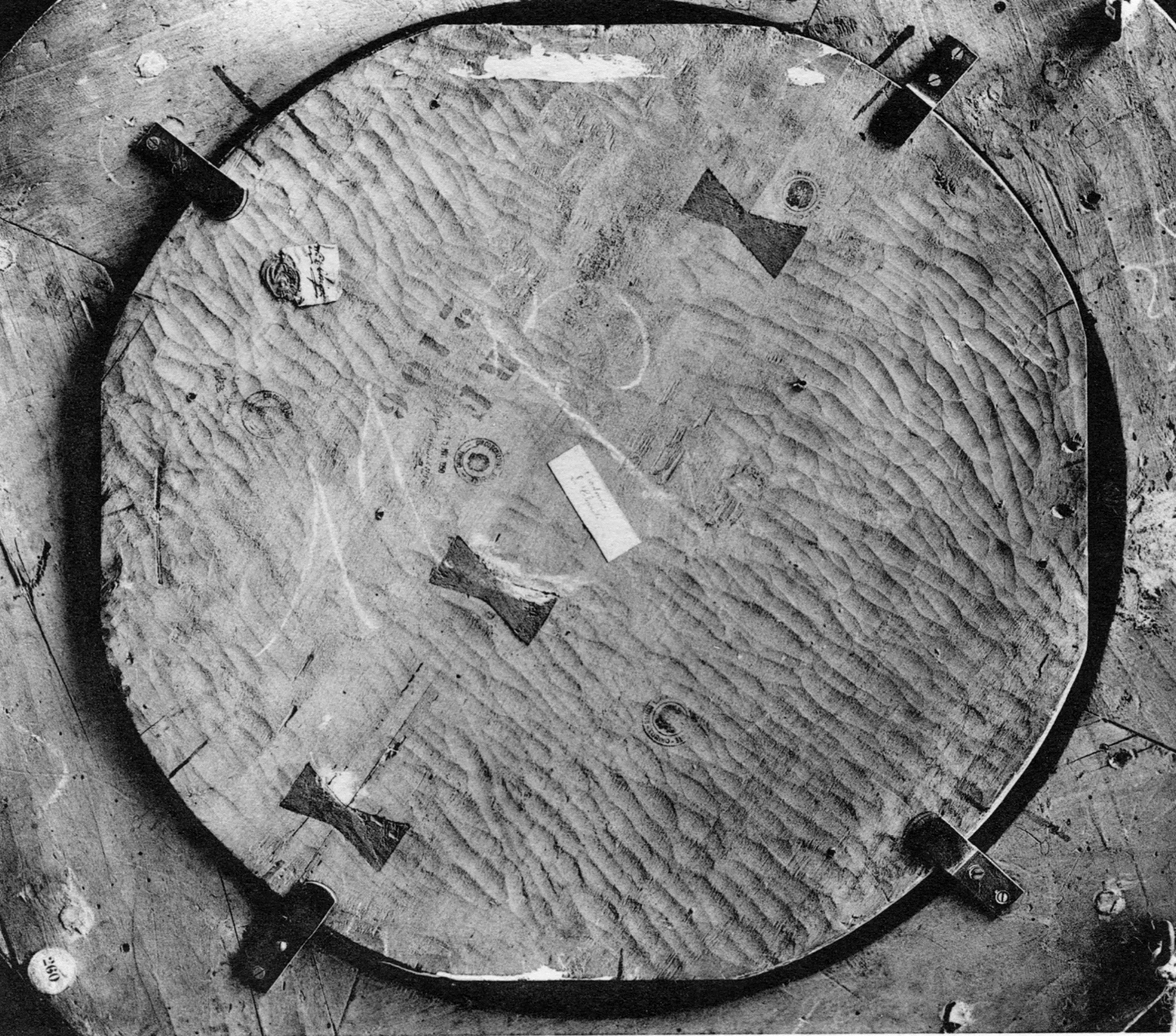

Figure 73 Rough cut using a gouge or paring-axe. (Il Sodoma (Giovanni Antonio Bazzi), Love and Chastity. – Paris, Musée du Louvre. Painting index, no. 811.)

Figure 74 Regular saw cut. (Leonardo da Vinci, The Virgin and Child with St Anne – Paris, Musée du Louvre. Painting index, no. 602.)

Figure 75 Cuts used for boards from the same panel: quarter-cut and plain-cut. (Master of Moulins, Female Donor Presented by Mary Magdalene – Paris, Musée du Louvre. Painting index, no. 166.)

Adze

The adze is a kind of axe with a thin, arched blade.15See the Glossary. A boss in the vault of the church of Saint-Agricol in Avignon16See Fig. 51. features the arms of the fustiers’ charity, ‘a griffin holding an adze in its claws’,17Mémoires de l'Académie de Vaucluse, 1907 dating from the 14th century.

Paring-axe

As to the paring-axe (doloire),18See Fig. 52. there is a conflict between Littré’s definition: ‘cooper’s axe used to smooth wood and cut hoops’, and that of Victor Gay: ‘large axe with a broad blade and short shaft’. Gay illustrates his definition with drawings and diagrams,19Gay 1928, I: 557–8. and the texts themselves support a definition less limited than Littré’s: ‘To Jehan de France, wood cutter [doleur de merrien], for his trouble and pay for smoothing 350 pieces of the aforesaid bois d’Ylland for a price of 22 sols per hundred.’20‘A Jehan de France, doleur de merrien, pour sa peine et salaire d’avoir dolé 350 pièces dud. bort d’Yllande au pris de 22 s. p. le cent’ ; Gay 1928, I: 165. It should be noted that the word used here for ‘cutter’ (doleur) refers to a craft equivalent to sawyer or raceur. The surface of the wood cut in this way with an adze or a paring-axe is marked with small, irregular cavities. The most characteristic panels in this regard include the Louvre’s Triptych by Giovanni Massone,21Gay 1928, I: 557–8. the altar frontal from the 13th-century Catalan School in the Museu Nacional d’Art de Catalunya in Barcelona22Fig. 113 (Painting index, no. 870). and the beautiful round panel from the Italian School, Love and Chastity (?), by Il Sodoma (1477–1549).23Musée du Louvre, Fig. 73 (Painting index, no. 811). The longer and shallower cavities in the wood suggest that a paring-axe was used, rather than an adze.

Draw-knife

The draw-knife (plane) is a kind of curved chisel with one or two handles,24See the Glossary. which was also used to smooth surfaces. Theophilus Presbyter (ca. 1070–1125) described the tool as ‘curved with the cutting edge on the inside and two handles, so that it can be pulled by both hands ... It is used to smooth tables, doors, and cases, until these objects are perfectly even’.25Théophile 1843: 31. The surface of wood finished this way is smooth, with furrows of varying depth, depending on the type of tool used and the pressure with which it was applied. These furrows running parallel to one another cross the surface of the panel from one side to the other (Fig. 72).

Wood chisel and mallet

The wood chisel and mallet26See Figs 56 and 62. give the prepared wood a coarse appearance. The cross-bars on the back of the support for Leonardo da Vinci’s Virgin and Child with St Anne offer a striking example of this cut.27Fig. 71 (Painting index, no. 602). Chisels were tools associated more with woodcarvers and fustiers than with carpenters. They were used for more refined, finished work. The Roman de Renart, which we know to have been composed in the 12th and 13th centuries, includes these charming lines:

N’y a au monde bête ni oiseau

Qui ne soit œuvre à ciseau28Roman de Renart, vol. III, p. 88.

(There is neither beast nor bird in this world

That cannot be shaped by the chisel)

Qui ne soit œuvre à ciseau28Roman de Renart, vol. III, p. 88.

(There is neither beast nor bird in this world

That cannot be shaped by the chisel)

The gouge is a kind of chisel with a curved, grooved blade that leaves shallower, less coarse marks on the wood. The marks it leaves on the surface are therefore longer and more concave (Fig. 73).

Fine cutting: the saw

Having felled the trees by axe, they were cut up into sections (ais or potz), whether for use in construction or as firewood, by sawyers or raceurs, who must have been specialised workers to some degree, as a specific name was given to their trade.29Editors’ note: Baltic timber was often split directly after felling and before export as planks or wainscot, see Gérard and Glatigny 1997: 59–60; Rief 2006. Nevertheless, the word raceur needs some explanation. We note that Frédéric Godefroy (1826–1897),30Godefroy 1881–1902. who is unaware of it, uses the terms rasse, resse, and resser instead, which he translates as ‘saw’, ‘sawmill’ and ‘sawing’ respectively. What is more, he does not detect them (the terms) before the end of the 15th century, whereas the Burgundian ducal accounts refer from as early as 1364–65 to ‘cabinets of good, clean oak, split by saw [fendu à la resse]’. The same text later refers to payments made to charpantiers and raceurs.31Prost 1902–1913, I: no. 432. The use of the term ‘split’ (fendu) might cast doubt on the translation of resse as ‘saw’ rather than ‘axe’. This hesitation is dispelled, however, when we read in the inventory of items found in the carpenter’s workshop at Lille Castle in 1388: ‘le soyeire à fendre bos’,32Prost 1902–1913, II, no. 2,336. or ‘saw for splitting wood’. The saw was not a widely used tool, which meant sawyers were much in demand.

The Duke of Berry’s (1340–1416) building accounts record wages paid in 1386 and 1387 to ‘two wood sawyers [soieurs] for sawing bort d’Illande’ and ‘several sawyers for sawing bort d’Irland and other wood needed to build doors, windows, frames [chapciz], and screens’ at Poitiers Castle. Seven sous a day were later paid, around 1400, ‘to Michelet du Haloy and Gilet Jaquet, plank sawyers [sieurs d’ais], for their troubles and for sawing and splitting lengthwise the aforesaid bort d’Yllande’. A 1527 inventory refers to ‘a large quantity of bois d’Almarche, sawn and unsawn [soyet et non soyet]’.33Gay 1928, I: 164, 165.

To conclude our discussion of these two tools – the resse and the scie – it might be suggested that the former was used to cut wood crosswise, while the second served to cut it lengthwise (de long) if we are to believe the quoted text from 1400. The other texts we have seen cannot, however, confirm this. The saws employed at that time strongly resemble those in use today: handheld rip saws and hacksaws.34See Figs 59 and 61. Water-driven saws also existed in the Middle Ages in the Vosges, with wind-powered versions in Estonia and the Åland Islands in the Baltic.35Deffontaines 1933: 133. Surviving texts tell us that in France, in 1384, ‘sawyers use sawmills [moulins à scie] to cut wood’.36Monget 1898: 59. We do not believe, however, that saws were used in the early Middle Ages. Tools of this type do not appear in the iconography of the trades until the end of the 15th century.37The saw does not feature in the joiner’s workshop in the 14th century (Fig. 62). The carpenters we see using them in Fig. 61 come from an engraving dated 1473. Le Rébus de Picardie, which includes a saw (Fig. 59), likewise dates from the 14th century. The Bayeux Tapestry, produced in the 11th century, shows shipwrights working exclusively with axes and adzes.38Moles 1949: 22, fig. 36.

Examination of the panels tells us that saws were used from the 14th century onwards. The Louvre’s Presentation in the Temple by Bartolo di Maestro Fredi (ca. 1330–ca. 1355),39Painting index, no. 715. is, as far as we know, the earliest evidence in that respect. Many 15th-century panels show more or less clear traces of the tool. One of the best 16th-century examples is Leonardo da Vinci’s (1452–1519) Virgin and Child with St Anne (Figs 71 and 74). It is not the case, however, that every board that was sawn will necessarily bear the marks:40Information provided by R. Blais. 16th-century panels often display uniform and even polished surfaces that suggest advances in tool quality and, no doubt, use of a plane.

The saw was, therefore, employed in the Middle Ages, but apparently only sparingly. Making planks this way no doubt remained a tedious task, and woodworkers would have preferred to make direct use of a simply squared tree trunk.41Deffontaines 1933: 133. There can likewise be little doubt that the medieval prohibition on felling trees by saw was dictated by concern for better forest management. The saw has indeed been accused of ‘crushing the surface of the cross-section and harming the sprouting ability of the stumps’.42Blais 1947: 167. Jacques Chevalier has noted in a similar vein that ‘the saw severs the fibres brutally; it slices through them, rather than following them intelligently and being guided by nature’.43Chevalier 1932: 121. It was only in the 17th century that the saw began to feature as an emblem of the carpenters, as we see in an engraving in the Cabinet des Estampes, which shows the arms of the carpenters fraternity in Paris.44Moles 1949: 20, fig. 34.

Mixed cutting

The different boards used to make a painting support were generally cut using the same method. There are cases, however, in which not all the boards used in a single support or in the secondary elements of the support were cut in the same way: we refer to these as ‘mixed-cut panels’. The cross-bars in Leonardo da Vinci’s Virgin and Child with St Anne (Fig. 71) are an example of this, as the cross-bars and the panel itself were not cut using the same method. The cross-bars were cut roughly using a mallet and chisel, while the support proper is entirely sawn (Fig. 74).

An example of mixed cutting of the different boards in a single panel is provided by Scenes from the Life of the Virgin from the 14th-century Navarre School in Barcelona,45Painting index, no. 392. the two panels from the Portuguese School46Portugal, 16th century, St Jerome, Lisbon (Museu Nacional de Arte Antigua) (Painting index, no. 269); Vasco Fernandez, Calvary Altarpiece, central panel, Viseu (Painting index, no. 4). and a painting from the late 16th-century Dutch School, The Dwarf of Cardinal de Granvelle Holding a Big Dog by Antonio Moro (1519–1576/78)47A fine example of three different cuts: axe, adze and saw. Cf. Fig. 70 (Painting index, no. 223). in the Louvre. These all bear the traces of two or three tools: saw, adze and riving knife.48The riving knife (départoir) is a splitting tool (see the Glossary). This apparently unusual method does not seem to have been used elsewhere. We have identified a single Italian example from the 14th-century Umbrian School.49School of Alegretto Nuzi, The Mystical Marriage of St Catherine of Alexandria, Paris (Musée du Louvre) (Painting index, no. 667). The different cuts seem to have been assembled in a certain order, but we do not think this is the result of a conscious decision. Various boards, cut at different times, may simply have been pulled from a dealer’s stock at the moment in question to construct a panel.

Finishing the surfaces: the plane

Wood ‘smoothed’ in this way still presented too uneven a surface for painting. ‘In the first place’, Cennino Cennini (ca. 1370– ca. 1440) instructs, ‘a panel ... must be prepared, on which to paint the picture. Let it be made quite smooth: if it be defaced with knots, or if it be greasy, you must cut it away as far as the grease extends, for there is no other remedy.’50Merrifield 1849: Part VI, CXIII, 67. In other words, before applying a more or less thick preparatory layer on the surface to be painted, it needed to be levelled off. According to Antoine Moles, the plane (rabot) did not make its appearance until the 14th century, after the saw.51Moles 1949: Préambule, XIV. It appeared toward the end of the 15th century in the Iconographie des métiers (Fig. 62), and use of planes had become widespread by the end of the 16th century: ‘New, cloudy wine can be cleared very well by placing in the vessel beechwood chips or shavings produced by the axe or plane, and the wine will clear in two days.’52Gay 1928, I: 733. Editors’ note: See further Van der Sterre 2001.

In seeking to identify the archetype of this tool, it is interesting to read in Monget’s study La Chartreuse de Dijon, a contract between Jehan Perrenin and Jehan Maluel (Jean Malouel) (1370/75–1415): ‘The painter bought some scrapers [racloirs], sharpened steel tools, to finish [pour polir] the surface of the wood.’ The receipt for this transaction, dated 11 February 1398, is worded as follows: ‘To Jehan Perrenin, smith [feure], and Gilet, the plumber [fontenier] residing in Dijon, for the sale of thirty-five sharpened iron scrapers [racles de fer acérées] made by the said Jehan and supplied to Jehan Manuel [sic.].’53Monget 1898: 296. The finish obtained in this way was, however, variable as we can see through the thin preparatory layers applied by certain artists. In many cases, therefore, the surfaces to be painted remained uneven and rough, as we find in the two panels from the Loire School painted around 1460.54Le Mans, The Virgin and Child with St Benedict (Painting index, no. 177); The Adoration of the Magi (Painting index, no. 178).

Cutting methods

The different sections: end-grain, quarter-cut, plain-cut

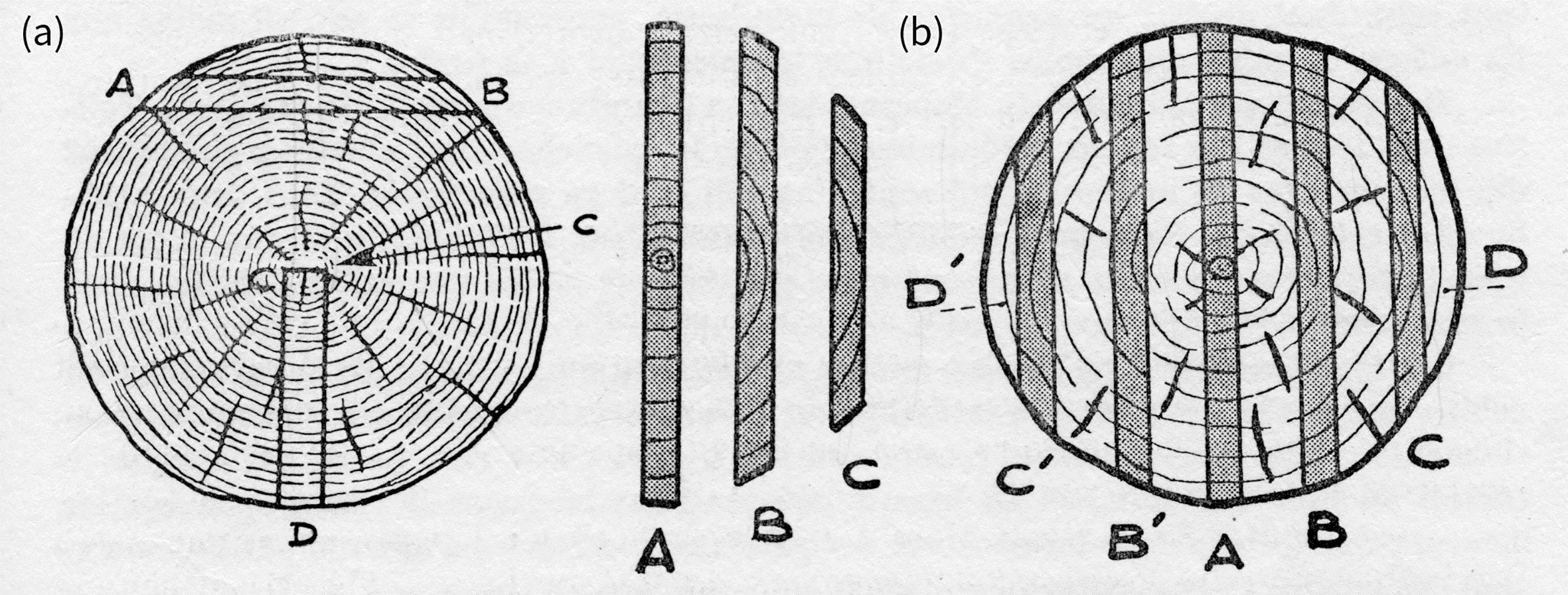

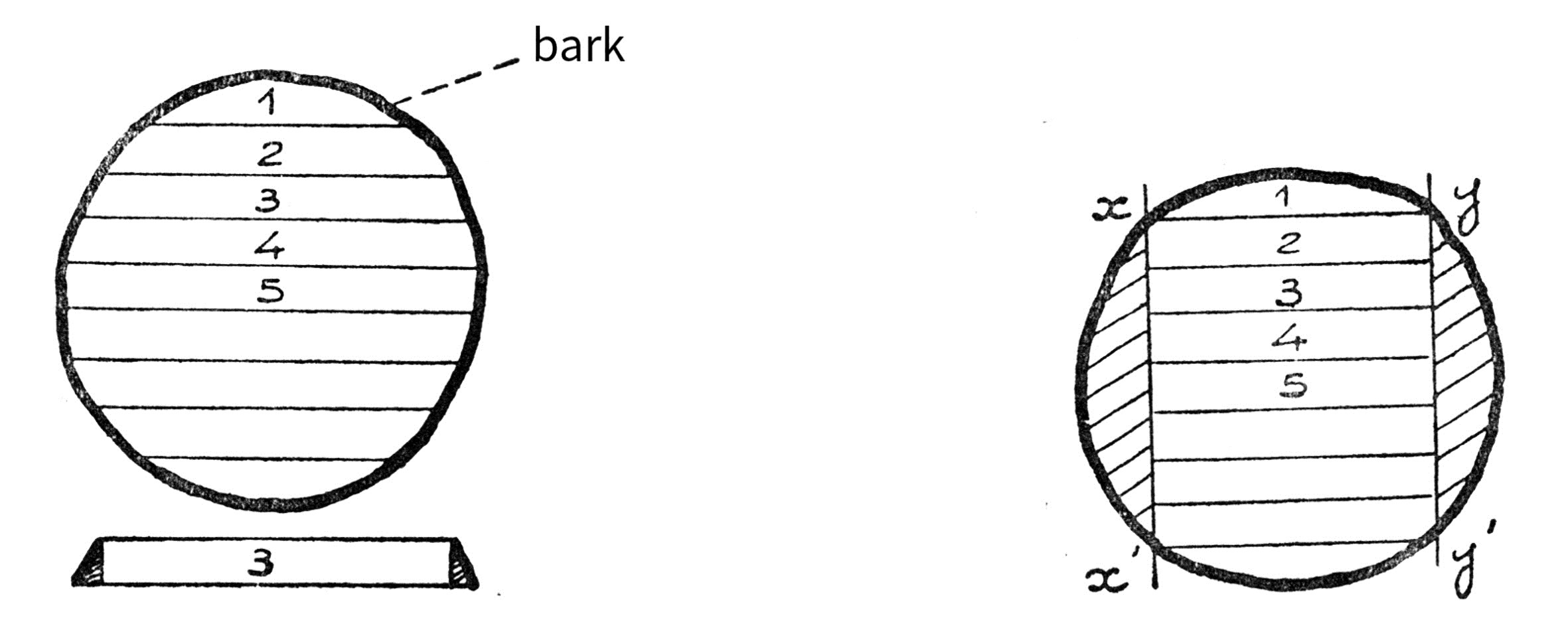

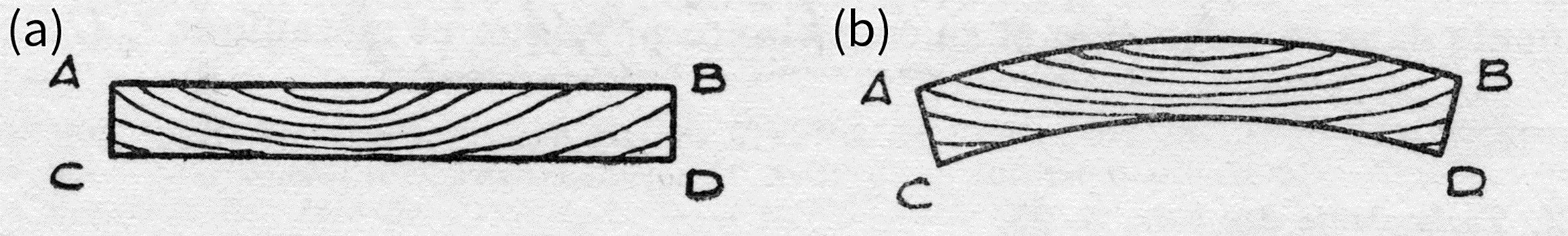

Figure 76 shows what we mean when we describe a board as ‘end-grain’, ‘quarter-cut’ or ‘plain-cut’, depending on whether the tree trunk55Cf. Chapter 2, section entitled ‘Anatomical structure’. has been cut transversely, radially or tangentially.

Figure 76 (a) Cross-section of a tree (AB = plain-cut; CD = quarter-cut); (b) the different vertical sections of a tree from the centre to the bark (A = quarter-cut board; B = board between plain- and quarter-cut; C = plain-cut board; D = sapwood).

Transverse or end-grain section

This cut is never used in carpentry or joinery: ‘since boards are less apt to crack when the heart of the tree is not at their centre’.56Duhamel du Monceau 1764, II: 662. There are no examples of panels made of wood cut in this way (Fig. 76a). If the method was unsuitable for joinery, it would have been even less appropriate for a painting, which was expected to last a long time.

Radial or quarter-cut section57Editors’ note: It must be emphasised that the majority of oak planks used for panel paintings until the 17th century were already cleaved into wainscots ready for use at the time of import. These were upon arrival sometimes further cleaved or sawn into thinner boards; see Streeton and Wadum 2012: 88–92.

This section has always been the most widely used and prized. The contract for a painting of the Virgin and Child, which Pierre d’Arbois, Lord of Châteauneuf d’Oze, in the diocese of Gap, presented to Pierre Bœuf, resident and citizen of Aix on 3 June 1497, specified not only the type of wood to be used for the commission, but also the part of the wood. The panel was to be five pans high and made of ‘heart of walnut’.58Labande 1932, II: 112.

Wood cut from the heart of the tree was highly sought after for its exceptional physical qualities. Boards of this kind were more durable, less ‘apt to crack’, their structure was more visually attractive – oak especially – and their greater width made them even more prized.59Editors’ note: See the Antwerp Liggeren and guild ordinances on the quality of wood in altars in Van Der Straelen 1855. These boards, Duhamel du Monceau (1700–1782) adds, are:

less apt to crack when the heart of the tree is cut along the diameter, as is often done when seeking wider boards ... To understand the importance of sawing trees along their diameter, and not in just any direction, it should be noted that, when they have been quartered, one observes on certain oak planks, bright patches that resemble the inside of a peach kernel. These patches are so bright, that some people call them ‘mirrors’;60Editors’ note: Caused by intersecting the medullar rays going radially from the pith to the bark. they are referred to more accurately in Paris as ‘figure’ [mailles], and wood displaying it is highly prized, especially that used to make panels in joinery, because it shrinks less than other types, and is less apt to warp [tourmenter] or crack [fendre].

Monget confirms Duhamel du Monceau’s definition of the quarter-cut (sur maille). When cut in the direction of the medullary rays, he writes, the resultant boards display patterns or figure that create an attractive effect in joinery. Both authors ascribe the same qualities to this cut: these boards are more resistant to humidity and extremes of temperature, so they crack and warp less than those cut perpendicular to the rays.61Monget 1898: 59.

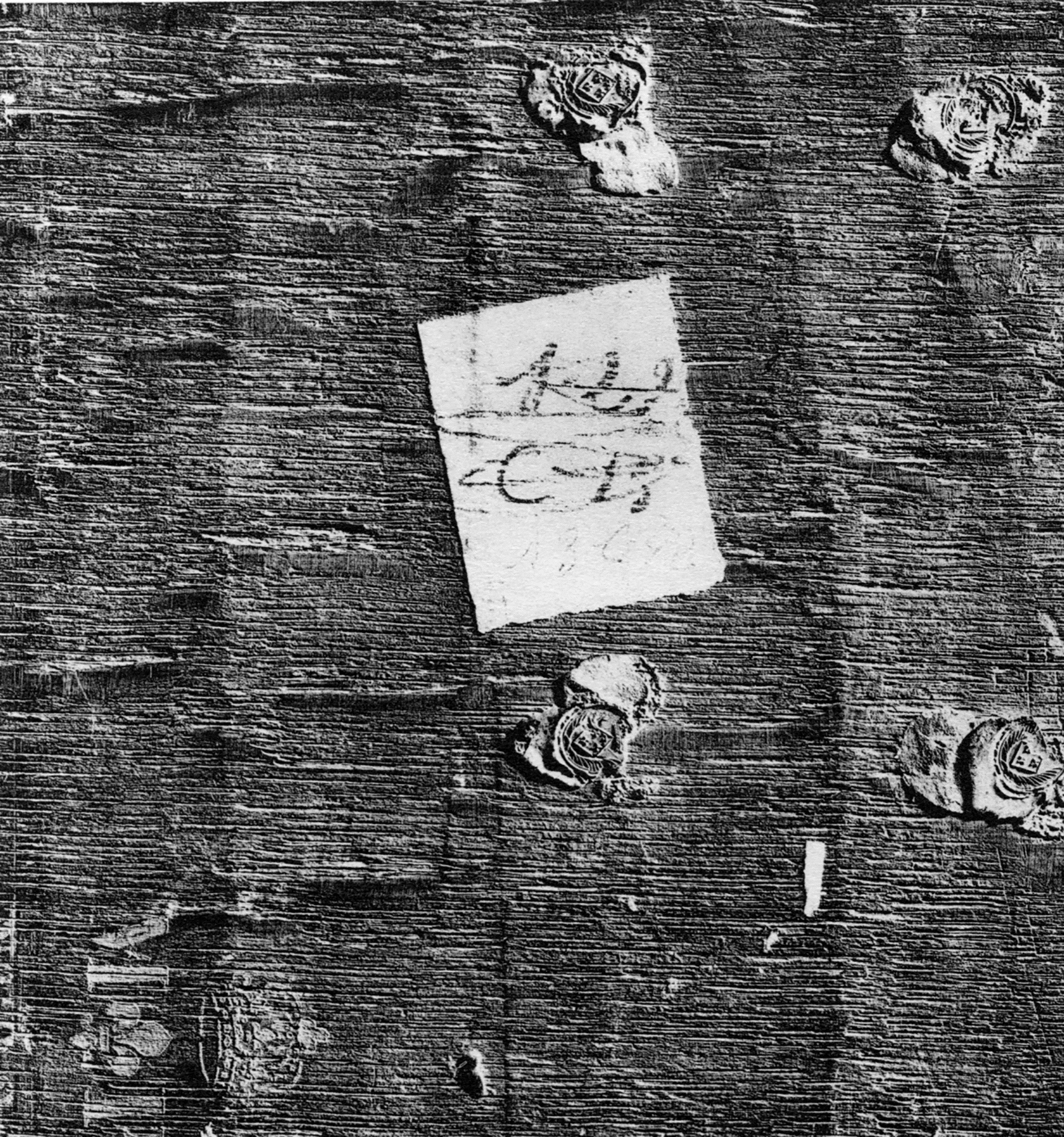

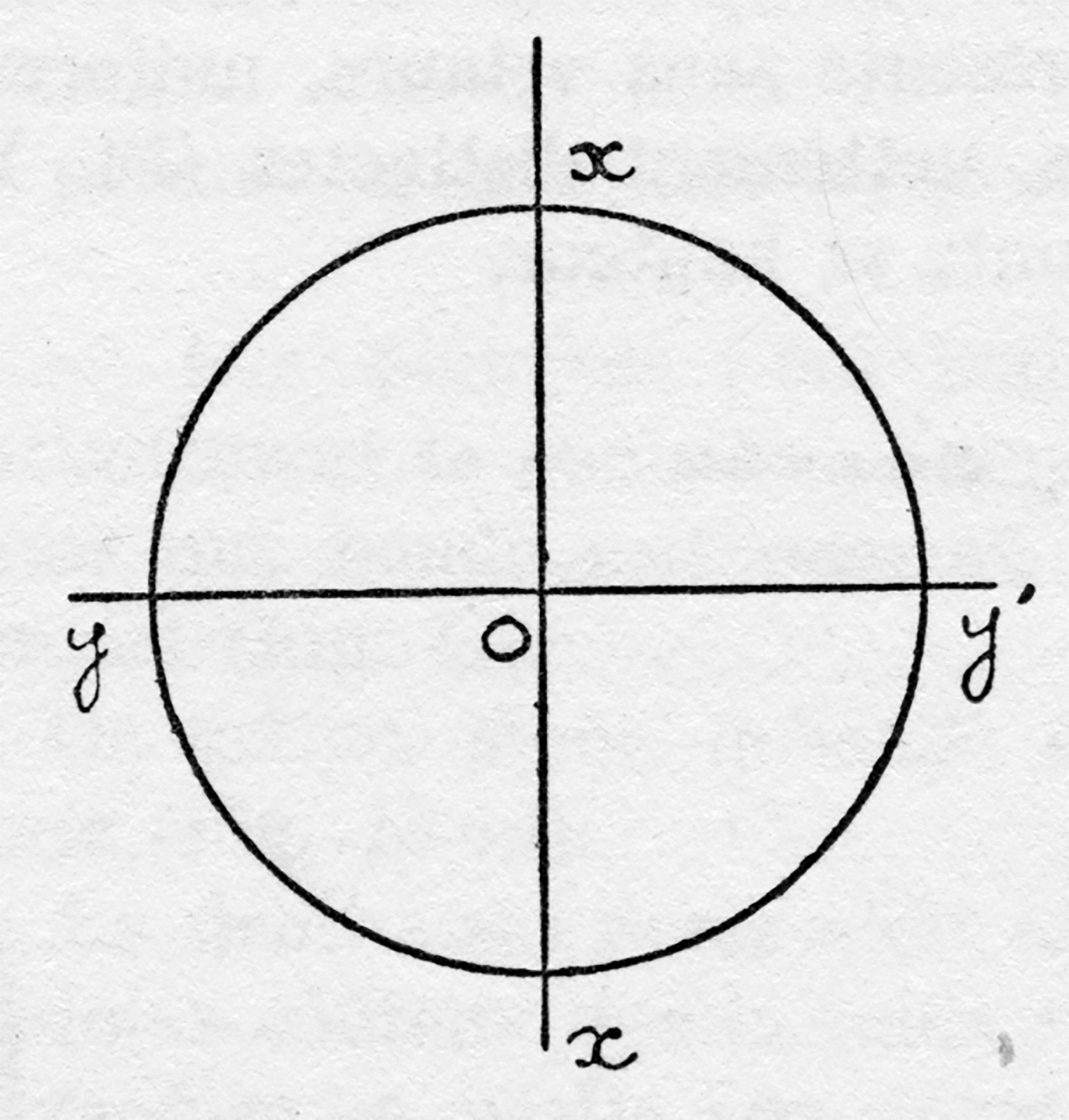

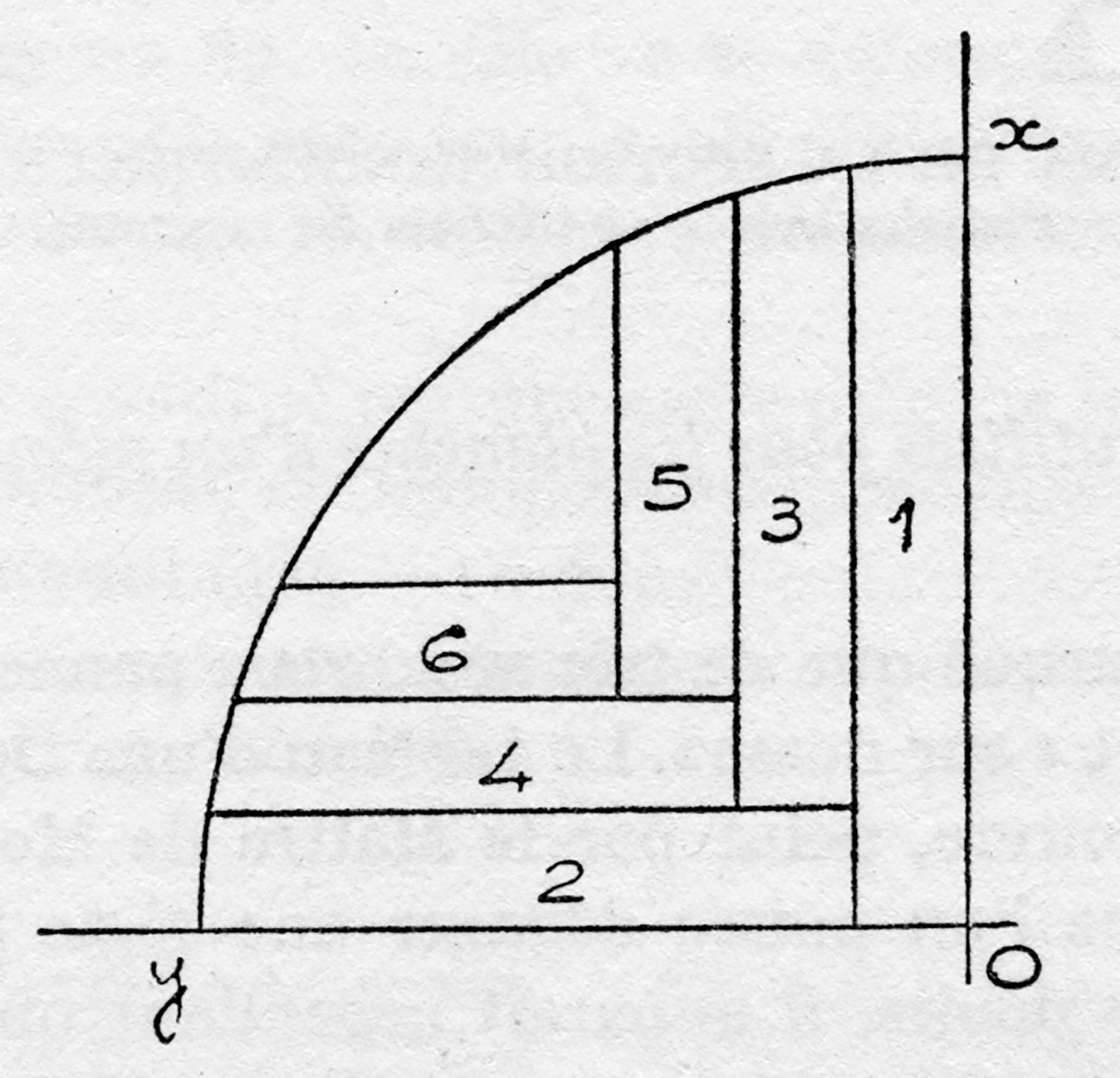

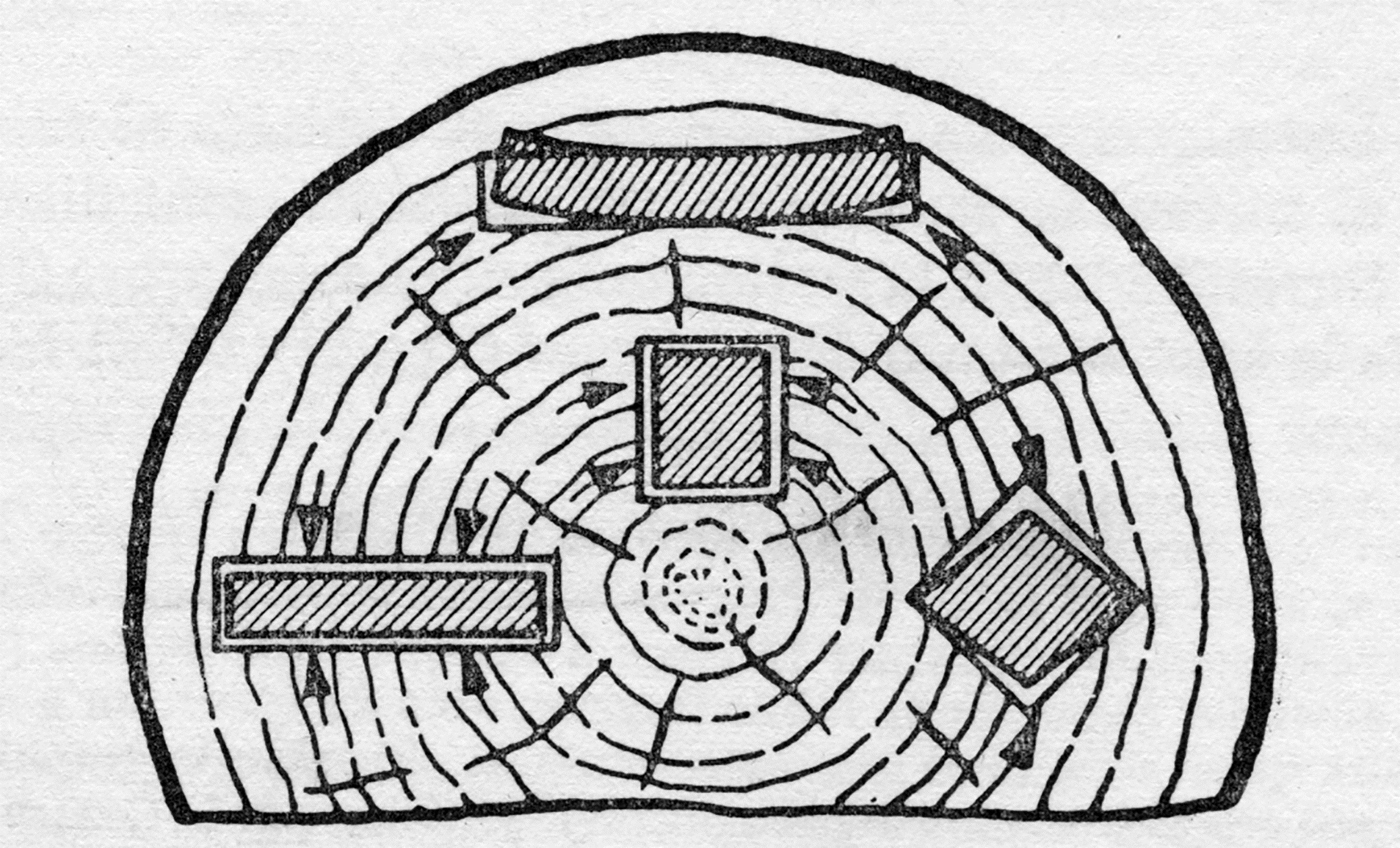

These accounts – the earliest of which dates back to the 18th century – of how ‘quarter-cut’ boards were sought after for aesthetic and conservation reasons are fascinating documents. It is clear that nothing relating to the processing of the wood was left to chance, as we find the same specifications in artists’ contracts from the Middle Ages onward, which we can moreover confirm by examining the panels themselves. Quarter-cut wood was expensive and prized, and was indeed frequently used to make supports for paintings, from the 16th century in particular.62Editors’ note: See Klein 2012. It is especially common in Flanders and France, particularly in the panels used for French portraits. These are generally made of oak cut radially.63Quarter-cut (sur maille) is also referred to in French as sur quartier. Its main use nowadays is in cabinetmaking. Only oak is now quarter-cut in France, and then only in small quantities. The first stage is to split the log into four quarters by two cross-shaped sawcuts, x, x’ – y, y’ (Fig. 77). Each quarter is then sawn, beginning with the widest side, taking care to rotate the piece with each sawcut (Fig. 78). The sawing sequence is 1, 2, 3, 4, etc. This produces narrow planks; ‘quarter-sawn’ is obtained near the heart, after which the planks are ‘rift sawn’ (faux quartier). (The information and diagrams in the second part of this chapter were kindly provided to us by the Centre technique du Bois.) One of the finest examples of figure in an oak panel is the Portrait of Elizabeth of Austria from the School of François Clouet, in the Louvre.64See Fig. 116 (Painting index, no. 138).

Figure 77 Diagram of radial or quarter-cut section, first stage: the separation of the log into four quarters, x, x’ — y, y’.

Figure 78 Diagram of radial or quarter-cut section, second stage: splitting a quarter into quarter-cut (1, 2) and rift-cut (3, 4, 5, 6) boards.

Tangential or plain-cut section

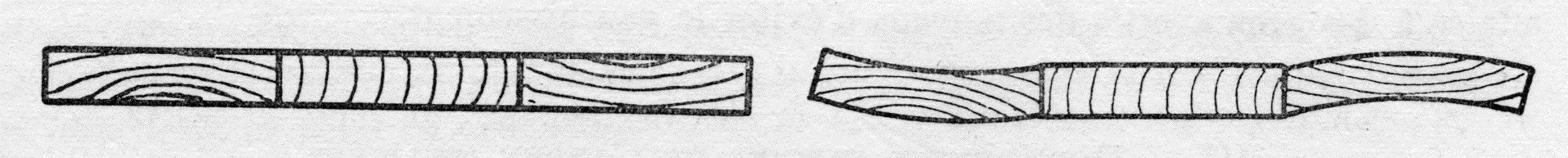

Boards that are cut using neither the first nor the second of these methods are described as ‘plain-cut’, following the tangential section of the tree (Fig. 86). Logs processed in this way are cut across their full width (Fig. 79). It is a simple cut and the one most beneficial to the sawyer.65Editors’ note: The only wastage in this case comes from the sawcuts and averages 8–10%, depending on the thickness of the planks and the gauge of modern tools. If the planks are subsequently squared off, total wastage from the undressed lumber (i.e. cut wood retaining its bark) rises to 45–50% by volume. This is the most common method for producing standard timber, especially for softwoods and hardwoods in France. It was widely employed for the boards used to make painting supports, and most old panels were cut this way.66Editors’ note: This way of cutting does not apply to oak. The surface of the wood is uniform and free of graining. In some cases – softwoods, for instance – clearly visible parallel lines furrow the surface of the board all the way up (Fig. 31).

Figure 79 Diagram of a tangential or plain-cut section: squared-off plank and log waste.

Cuts used for boards from the same panel

Lastly, we also noted that a great many panels are made up of both quarter-cut and plain-cut boards. The painting of a Female Donor Presented by Mary Magdalene by the Master of Moulins (ca.1475–ca. 1505) in the Louvre is one example.67See Fig. 75 (Painting index, no. 166). While it does not appear possible to infer a rule for individual schools based on observation of how these different cuts were assembled, a certain choice nevertheless seems to have prevailed in all of them, right from the beginning of the Middle Ages. We did notice, however, that certain countries, such as Flanders, tended to use quarter-cut boards, while Italy was more likely to use plain-cut ones.68Editors’ note: Until the introduction of the sawmills, oak for panel paintings was split radially out of the tree trunk. In addition to this preference, care was taken to alternate cuts, illustrating the detailed knowledge of wood that existed in the period in question.

Figure 80 Shrinkage of different cuts according to where they originate in the trunk

(the arrows indicate the direction of the maximum tangential shrinkage).

(the arrows indicate the direction of the maximum tangential shrinkage).

The following analysis sets out the benefits and drawbacks of each of these methods:

•Quarter-cut only. Quarter-cut boards joined side by side cause minimal warping, which means in practical terms that the panel will not warp if one face is not painted. This is a good method, therefore, from the point of view of warpage (Fig. 80).

•Plain and quarter-cut. Warping is also reduced if plain and quarter-cut boards are used together (Fig. 81).

•Alternated plain-cut. Plain-cut boards are inferior, as they are more likely to warp. They are cheaper than quarter-cut boards, however, and so were generally the most commonly used. The consequences of this cut can be corrected to some extent.

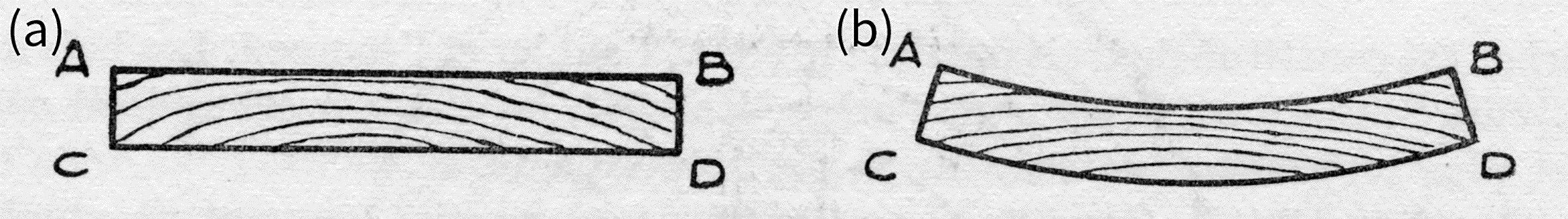

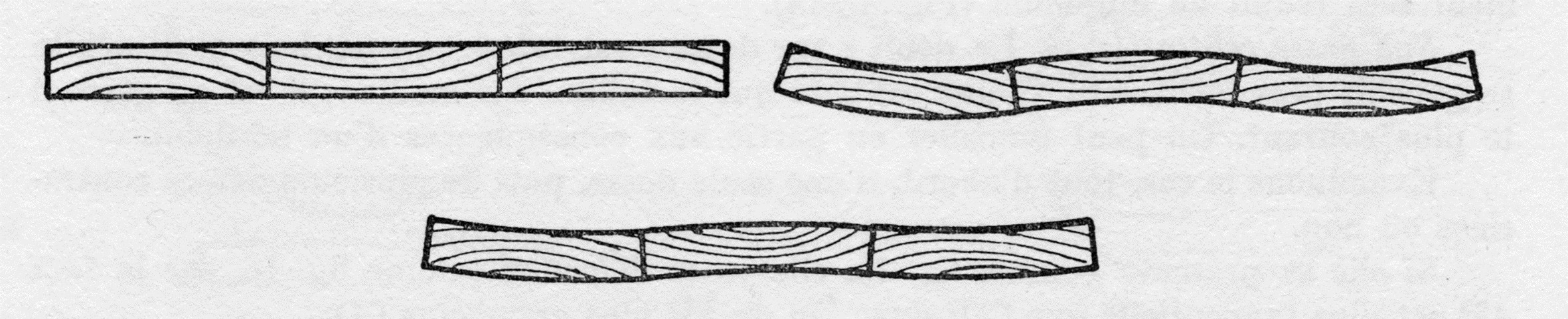

Let us begin by considering a single plain-cut board, and then several such boards joined together, in both alternating and non-alternating fashion. A board positioned as shown in Fig. 82a will warp in the manner illustrated in Fig. 82b, because surface AB is more tangential than CD; there is greater distortion in AB therefore than CD. If it is positioned as in Fig. 83a, it will warp as illustrated in Fig. 83b, for the reason already described. In other words, if the panel consists of a single wide board, it will warp in the way shown in Fig. 82b or Fig. 83b. If the panel is made of several such boards, it will be subject to maximum warping (Fig. 84). However, if the quarter-cut boards are alternated, the warping of the panel will be minimised to the greatest possible extent (Fig. 85).

Figure 82 (a) Single plain-cut board; (b) maximum warping on the upper surface (AB), which is the most tangential.

Figure 83 (a) Single plain-cut board; (b) maximum warping on the lower surface (CD), which is the most tangential.

Using quarter-cut boards thus remains the best way to prevent the panel from warping. A combination of plain- and quarter-cut boards is the next best method for producing a successful wooden support, followed by alternating plain-cut boards. We studied this matter based on a large number of observations, which we initially believed to be random. However, examination of a number of panels constructed using one of the aforementioned methods suggests that these were in fact people who knew the ways to prevent warping.

Use of different parts of the tree: surface flaws, deterioration

The tree consists of three parts: heartwood, sapwood and bark.69Cf. Chapter 2, ‘Wood technology’. Standard lumber is always from the heart of the tree, as the tissues in this zone are denser and more durable than those in the outer part. Nevertheless, planks cut from one or other of these areas will display surface flaws, the most common of which are knots and cracks.70Cf. Chapter 2, ‘Wood technology’. Anomalies related to the chemical composition of the wood, which add to the structural flaws represented by knots and cracks, determine the changes that occur in the colour of the wood and its physical and mechanical consistency.71Campredon 1949: 33. Decay and rot are the two main causes of changes in the chemical composition. Wood that presents any of these features is totally unsuitable for joinery and carpentry, as the historical documents below attest.

Sapwood and bark

Sapwood (aubier in present-day French) is referred to in historical French texts as auber, aube, aubour or obéi, and should not to be confused with the Provençal word for poplar (aube).72‘Aube ou peuplier blanc, appelé aussi peuplier de Hollande, ou ypréau’: Campredon 1949: 81. There is little scope for ambiguity, however, between the two meanings of aube when reading the relevant documents. On 7 February 1446, for instance, when Enguerrand Charonton (ca. 1410–ca. 1466) (or Quarton as he is usually called in English-language literature) was commissioned by Isoarde Gavarron, native of Tarascon and widow of Nicolas de Montfaucon, to paint an altarpiece for the church in that town, measuring six pans73For the conversion of measurements see Mémoires de l'Académie de Vaucluse 1939: 87. high and twelve wide, on bois d’aube.74Labande 1932, I: 77. This plainly refers to timber and not to sapwood. The same is true when Canon Quienet commissioned an altarpiece on 22 October 1505 in Carpentras from the fustier and joiner Jean Vial (Vialis) from Cavaillon, specifying that the body was to be made of aube and the outer parts from walnut.75Mémoires de l'Académie de Vaucluse 1939: 99.

The scope for confusion is further reduced by the survival of guild regulations to guide us. When aube is specified as the wood to be used for the support in certain contracts in Provence, this is a reference to poplar. On the other hand, where the statutes of woodworking guilds explicitly prohibit aube as unsuitable for construction, this is sapwood. The Registre of Étienne Boileau (ca. 1200–1270), from 1260, specifies that ‘Coopers working in Paris may only make barrels in one of four ways ... that is to say using heartwood oak without sapwood [sans aube].’76Étienne Boileau, Registre, pp. 103–4, after Gay 1928, I: 164. We therefore find references to ‘oak without sapwood [aubier]’, ‘walnut without sapwood [obéi]’, and so on. The type of wood and spelling of the term vary, but the rule remains. Numerous surviving texts impose and define this practice, and specify the penalties for failing to comply with it. Was the job to be done in ‘all wood’? – sapwood and bad wood [morbois] were excluded.77Fons 1841: 23. Was walnut to be used? – ‘Let there be no sapwood or decayed wood, and let none make a table from woods of whatever kind in which there is any sapwood in the joins or any rot whatsoever.’78Ordonnances des rois de France, vol. XX, pp. 609–10, art. 5.

The juxtaposition of ‘sapwood’ with terms such as morbois (mort-bois: bad wood), merrien eschauffé (decayed wood), pourriture (rot) and so on gives it a clearly pejorative connotation. Sapwood was associated with the ‘waste’ from the tree, was unsuitable for joinery and was prohibited by guild regulations.79Editors’ note: See the guild regulations for Antwerp altars in Van Der Straelen 1855. See also Van Damme 1990: 193–236. Unscrupulous woodworkers who cut their boards too close to the sapwood or who dared make furniture or assemble panels that retained any trace of sapwood risked extremely severe fines. These are set out in the regulations of the Paris huchiers (1467),80Ordonnances des rois de France, vol. XX, pp. 609–10, art. 2, 3, 4, 5 and 6. of their fellows in Noyon (1398),81Fons 1841: 23, note. and in those of the Paris woodturners (1467),82Arch. Nat., Y7, fo 77–79. the painters and sculptors of Abbeville (1508),83Thierry 1835, IV: 343. and the painters’ guild in Ghent (1338).84Dehaisne 1886, I: 329, art. 7.

Jean Campredon explains that ‘while heartwood keeps perfectly well over a great many years, sapwood is not very durable; it is rapidly attacked by fungus or insects. It rots quickly in contact with the ground. In damp conditions, it is rapidly invaded by destructive fungi; it often falls prey in parquet to the all-too-familiar insects responsible for boring tiny holes in wood. It is therefore essential that sapwood be rejected.’85Campredon 1949: 27. Since sapwood is the focus of insect attacks, it can be readily identified in an old board. It contrasts with the rest of the board in terms of its consistency and state of preservation, generally displaying deep tunnels, which multiply and are superimposed in bands or strips, depending on the cutting method. The healthy parts are heartwood and the worm-eaten parts sapwood.

It is very unusual to find sapwood in supports made in France and Flanders, where its use was prohibited. By contrast, the contracts made in Spain with the painters Luis Borrassà, after 1392, and Pedro Nunyz, around 1515, are less precise. They prohibit the use of wood which is not ‘seasoned’ and ‘good’, but go no further than that. We have identified several panels in Spain and especially in Portugal in which sapwood has been used. The altar frontal of fruitwood from the 13th-century Catalan School86Scenes of the Martyrdom of St Lawrence, Barcelona (Painting index, no. 371). was cut in part from a softwood with the consistency of cork, with all the appearance of sapwood, while the piece as a whole, cut from a healthy part of the tree, has an entirely normal consistency. The same is true of an Annunciation on Scots pine from the 15th-century Spanish School in the Musée des Arts décoratifs in Paris:87Painting index, no. 857. the panel displays a curious pattern of worm attack along three vertical strips on the sides and in the middle. The worm-eaten areas represent only part of each strip, which is otherwise entirely sound. Portugal, like Spain, provides numerous examples of this phenomenon, including the panel with St James and St Hermogenes in the Lisbon polyptych by the Master of Santiago.88Lisbon (Museo Nacional de Arte Antigua) (Painting index, no. 285). Cf. in the Painting index the Portuguese paintings with the following numbers: Gregorio Lopes, nos. 270 and 271; the Master of Viseu, no. 310; Vasco Fernandez, no. 313; Nuno Gonçalves, no. 305; Cristovâo de Figueiredo, no. 265A. Each of the planks making up this support are substantially worm-eaten on the two sides.

Lastly, the bark is never used for woodworking. All the same, we discovered the odd and unique case of a painted altar crucifix with the image of Christ on Scots pine with bark. This example, from the 12th-century Catalan School, relates to sculpture, however, rather than painting.89Catalan School (Lleida), 12th century (first half), Wooden Figure of the Virgin and Child, Barcelona, Museu Nacional d’Art de Catalunya (Inv. no. 15,926 ). Originated in Lleida.

Knots

‘Rotten knots [neuz pourris], wood that is half rotten [heuldry], broken or cracked, and decayed [merein eschauffé]’ are also classed as bad wood or morbois, as opposed to wood that is ‘seasoned, ready for use, adequate, and amenable [sec et prest, souffisant et convenable]’.90Prost 1902–1913, I: no. 2,683. They were prohibited in medieval France in the same terms as sapwood, and like the latter they crop up frequently in historical texts such as the Ordonnances des rois de France, Inventaire mobilier des ducs de Bourgogne..., and Statuts corporatifs, cited above. Article 16 of the ordinance governing the Paris huchiers (1467) is particularly clear: ‘Let none make a cabinet in Paris in walnut in which there is any trace of sapwood [auber], nor decayed wood [merrien eschauffé], nor any knots [neuz] showing on both sides, including in the bottoms [enfonceures], members [membrures], or fixtures, subject to the penalties set out below, that is to say, to be burned and a fine paid.’91Ordonnance des rois de France, vol. XX, p. 610, art. 2.

Cennino Cennini writes as follows in Il libro dell’arte in the section titled: ‘How you should start to work on panel or anconas’. Having first recommended choosing the wood carefully, he describes the next stage: ‘See that the wood is thoroughly dry; and if it were wooden figures, or leaves, so that you could boil them with clear water in kettles, that wood would never give you any trouble with cracks. Let us just go back to the knots or nodes, or other defects which the flat of the panel may display.’ Next comes the recipe for mixing glue and sawdust to fill any flaws and knots on the surface. He concludes with the words: ‘Fill the flaws of the nodes with it, and smooth down with a wooden slice, and let it stand. Then scrape with a knife point until it is even with the surrounding level.’92Cennini 1933: Part VI, CXIII. This text, which was written in the late 14th to the early 15th century suggests that the rules governing the selection of wood were less strict in Italy than in France. In providing a formula for concealing knots in the wood, Cennino Cennini implicitly accepted the idea of using wood of this kind for painting supports.

In some cases, repairs like this could be quite radical for the largest knots. The support of the Man with a Bird Cage, attributed to Mathis Gothardt-Neithardt, known as Grünewald (ca. 1470–1528),93Strasbourg, Musée des Beaux-Arts (Painting index, no. 435). has a knot on the back that was repaired using a piece of wood that is visible from the front. Knots were thus plugged either with wood-paste or a piece of wood.94Ullmann 1994.

Whatever precautions were taken and sanctions threatened, we still find flaws in the wood used for supports in many schools. This undoubtedly reflects the nature and quality of the wood species employed, and the direction in which the boards were cut. The oak used by the northern French and Flemish schools, for instance, is much finer quality than that found in the southern French School;95Editors’ note: Klein 1984. poplar, elm and chestnut likewise offer a less smooth surface. Lastly, the rigour with which the laws were enforced was greater in some regions than in others. Be that as it may, we found the wood with the most knots in the Portuguese School, almost all of which are chestnut panels from the 16th century (Fig. 86). A few examples are also found in Italy – most notably in the poplar supports used by the Florentine, Milanese and Veronese schools96Painting index, nos. 620, 656 and 816. – and in France – softwoods in general in western Provence, in the circles of Louis Bréa (ca. 1450–1522/25)97Spruce, see Fig. 87. and Jacques Durandi (ca. 1410–ca. 1469).

Decay98Editors’ note: There is an abundance of articles on the decay of wooden artifacts and panel paintings. Here is a brief selection: Koller and Prandtstetten 1998; Dardes and Rothe 1998; Journées sur la conservation restauration des biens culturels, Colloque de l'ARAAFU 1989; OPD restauro 1988; Ciatti et al. 1999; Gril 2010; Phenix and Chui 2011; Stoner and Rushfield 2012.

Of all the defects of wood, material that was decayed (eschauffé) seems to have been feared the most. The texts that refer to it99Ordonnances des rois de France, vol. XVI, p. 611, art. 14,15,16, 21: ordinances affecting the Paris huchiers, approved by Louis XI, 24 June 1467. display considerable knowledge of wood technology. Just as there was an understanding in the Middle Ages of the composition of wood and its anatomical structure, people were also aware of the flaws that could occur in that structure and the anomalies arising from deterioration in its chemical composition.

Decay (eschauffure) causes deterioration in the wood, manifested by changes in its physical and mechanical consistency. The tissues become soft and can alter to the extent of total destruction.100Campredon 1949: 33–5. The Middle Ages in France, in prohibiting sapwood, knots, and decayed or deteriorated wood for woodworking purposes, and by specifying this in guild regulations, kept tight control on those who used it in that period and even beyond. There was blanket condemnation of anything that was not durable and of good quality, and of everything tending towards mediocre and routine work. Words such as ‘choice’, ‘quality’ and ‘perfection’ were the only ones to which woodworkers could aspire, and were also the only qualifiers appropriate for works of art of this period.

1 Moles 1949: 152–3. »

2 Prost 1902–1913, II: nos. 2331, 2333–36, 2338, 2341. »

5 ‘VI journées de lui et XV journées d’autres charpantiers, pour abatre, cognoier et asseoir III traines de bois pour faire dessus la maçonnerie du mur’; Delaville-Le Roulx 1878–1881, I: 45, no. 235. »

6 Delaville-Le Roulx 1878–1881, I: 369, no. 1,786. »

8 Monget 1898: 293. »

9 Deffontaines 1933: 148. »

10 Littré 1863–1877. »

12 Catalan School, 13th century, Scenes from the Life of the Virgin, Barcelona (Painting index, no. 893). »

13 Blais 1947: 181. »

14 Monget 1898: 59. »

15 See the Glossary. »

19 Gay 1928, I: 557–8. »

20 ‘A Jehan de France, doleur de merrien, pour sa peine et salaire d’avoir dolé 350 pièces dud. bort d’Yllande au pris de 22 s. p. le cent’ ; Gay 1928, I: 165. »

21 Gay 1928, I: 557–8. »

25 Théophile 1843: 31. »

29 Editors’ note: Baltic timber was often split directly after felling and before export as planks or wainscot, see Gérard and Glatigny 1997: 59–60; Rief 2006. »

30 Godefroy 1881–1902. »

31 Prost 1902–1913, I: no. 432. »

32 Prost 1902–1913, II, no. 2,336. »

33 Gay 1928, I: 164, 165. »

35 Deffontaines 1933: 133. »

36 Monget 1898: 59. »

37 The saw does not feature in the joiner’s workshop in the 14th century (Fig. 62). The carpenters we see using them in Fig. 61 come from an engraving dated 1473. Le Rébus de Picardie, which includes a saw (Fig. 59), likewise dates from the 14th century. »

38 Moles 1949: 22, fig. 36. »

40 Information provided by R. Blais. »

41 Deffontaines 1933: 133. »

42 Blais 1947: 167. »

43 Chevalier 1932: 121. »

44 Moles 1949: 20, fig. 34. »

46 Portugal, 16th century, St Jerome, Lisbon (Museu Nacional de Arte Antigua) (Painting index, no. 269); Vasco Fernandez, Calvary Altarpiece, central panel, Viseu (Painting index, no. 4). »

47 A fine example of three different cuts: axe, adze and saw. Cf. Fig. 70 (Painting index, no. 223). »

49 School of Alegretto Nuzi, The Mystical Marriage of St Catherine of Alexandria, Paris (Musée du Louvre) (Painting index, no. 667). »

50 Merrifield 1849: Part VI, CXIII, 67. »

53 Monget 1898: 296. »

54 Le Mans, The Virgin and Child with St Benedict (Painting index, no. 177); The Adoration of the Magi (Painting index, no. 178). »

55 Cf. Chapter 2, section entitled ‘Anatomical structure’. »

56 Duhamel du Monceau 1764, II: 662. »

57 Editors’ note: It must be emphasised that the majority of oak planks used for panel paintings until the 17th century were already cleaved into wainscots ready for use at the time of import. These were upon arrival sometimes further cleaved or sawn into thinner boards; see Streeton and Wadum 2012: 88–92. »

58 Labande 1932, II: 112. »

59 Editors’ note: See the Antwerp Liggeren and guild ordinances on the quality of wood in altars in Van Der Straelen 1855. »

60 Editors’ note: Caused by intersecting the medullar rays going radially from the pith to the bark. »

61 Monget 1898: 59. »

63 Quarter-cut (sur maille) is also referred to in French as sur quartier. Its main use nowadays is in cabinetmaking. Only oak is now quarter-cut in France, and then only in small quantities. The first stage is to split the log into four quarters by two cross-shaped sawcuts, x, x’ – y, y’ (Fig. 77). Each quarter is then sawn, beginning with the widest side, taking care to rotate the piece with each sawcut (Fig. 78). The sawing sequence is 1, 2, 3, 4, etc. This produces narrow planks; ‘quarter-sawn’ is obtained near the heart, after which the planks are ‘rift sawn’ (faux quartier). (The information and diagrams in the second part of this chapter were kindly provided to us by the Centre technique du Bois.) »

65 Editors’ note: The only wastage in this case comes from the sawcuts and averages 8–10%, depending on the thickness of the planks and the gauge of modern tools. If the planks are subsequently squared off, total wastage from the undressed lumber (i.e. cut wood retaining its bark) rises to 45–50% by volume. »

68 Editors’ note: Until the introduction of the sawmills, oak for panel paintings was split radially out of the tree trunk. »

69 Cf. Chapter 2, ‘Wood technology’. »

70 Cf. Chapter 2, ‘Wood technology’. »

71 Campredon 1949: 33. »

72 ‘Aube ou peuplier blanc, appelé aussi peuplier de Hollande, ou ypréau’: Campredon 1949: 81. »

74 Labande 1932, I: 77. »

77 Fons 1841: 23. »

79 Editors’ note: See the guild regulations for Antwerp altars in Van Der Straelen 1855. See also Van Damme 1990: 193–236. »

81 Fons 1841: 23, note. »

83 Thierry 1835, IV: 343. »

84 Dehaisne 1886, I: 329, art. 7. »

85 Campredon 1949: 27. »

88 Lisbon (Museo Nacional de Arte Antigua) (Painting index, no. 285). Cf. in the Painting index the Portuguese paintings with the following numbers: Gregorio Lopes, nos. 270 and 271; the Master of Viseu, no. 310; Vasco Fernandez, no. 313; Nuno Gonçalves, no. 305; Cristovâo de Figueiredo, no. 265A. »

89 Catalan School (Lleida), 12th century (first half), Wooden Figure of the Virgin and Child, Barcelona, Museu Nacional d’Art de Catalunya (Inv. no. 15,926 ). Originated in Lleida. »

90 Prost 1902–1913, I: no. 2,683. »

92 Cennini 1933: Part VI, CXIII. »

94 Ullmann 1994. »

98 Editors’ note: There is an abundance of articles on the decay of wooden artifacts and panel paintings. Here is a brief selection: Koller and Prandtstetten 1998; Dardes and Rothe 1998; Journées sur la conservation restauration des biens culturels, Colloque de l'ARAAFU 1989; OPD restauro 1988; Ciatti et al. 1999; Gril 2010; Phenix and Chui 2011; Stoner and Rushfield 2012. »

99 Ordonnances des rois de France, vol. XVI, p. 611, art. 14,15,16, 21: ordinances affecting the Paris huchiers, approved by Louis XI, 24 June 1467. »

100 Campredon 1949: 33–5. »